Starting edible oil refining manufacturing in Africa, to replace the imported, mass-produced brands, is now possible with the collaboration of experts in the field of oils : Henan Doing Mechanical Equipment Co.,LTD

Edible oil

Edible Oil Refining Production Line

We recommend the most suitable and cost effective edible oil refining production lines to start a local edible oil refining manufacture. Before starting an edible oil refining factory, it is very important to decide scale.

Crude oil obtained from expellers or solvent extraction, contains impurities. To make the oil edible, the impurities must be taken out; such a process is called “oil refining(oil refinery plant)”. Oil Refining (Oil Refinery Plant) means conversion from crude oil to direct human consumption, crude oil refinery, edible oil refinery, oil refinery projects and industrial purpose.

In general, oil refinery plant divides to 3 types: batch oil refinery plant, semi-continuous oil refinery plant, continuous oil refinery plant. These 3 oil refinery plants are used for different capacity. But the processes in each oil refinery plant are almost the same.

Edible Oil Refining Manufacturing Process

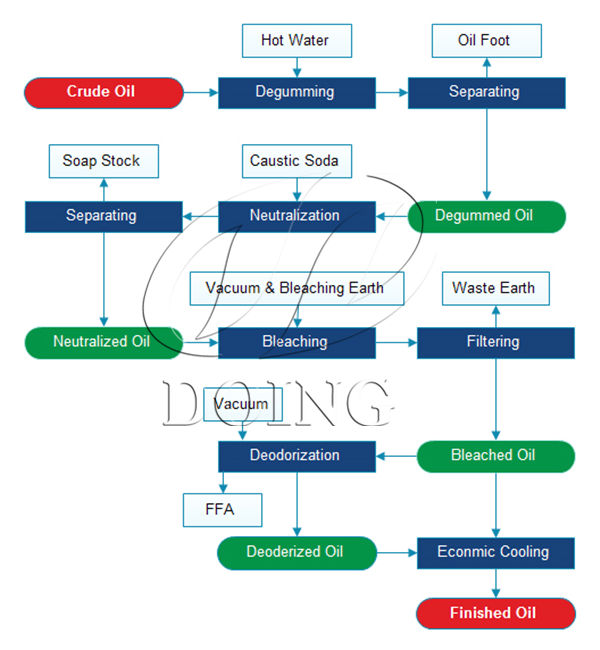

Crude oil--Degumming--Neutralize--Decoloring--Deodorizing--Cooling--Final oil

Edible oil refinery process flow diagram

Main process of edible oil refinery plant:

Degumming process of crude edible oil:Done to remove the aqueous phase from the lipids, and to remove phospholipids from the oil.

Neutralization process of crude edible oil:The neutralization step is necessary in edible oil refinery machine to remove free fatty acids from the oil.

Bleaching process of crude edible oil:Bleaching results in the removal of coloring materials, phospholipids and oxidation products.

Deodorization process of crude edible oil:Deodorization results in the removal of odour from the oil.

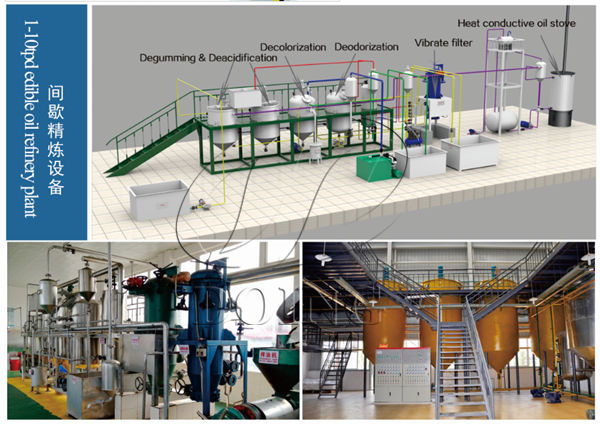

Small scale edible oil refinery plant introduction :

Specification of batch edible oil refinery plant:

| 1.Batch oil refinery plant | |

| Capacity (Ton/Day) | 1-10TPD |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castoroil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil,etc. |

| Main equipment: | Refining pot, Decoloring pot, Deodorization tank, Steam generator, Vibrate filter,Electricity distribution control, Air compressor |

Pictures show of batch edible oil refinery plant:

Batch edible oil refinery plant

Semi- continuous edible oil refinery plant introduction :

Specification of Semi- continuous edible oil refinery plant:

| 2. semi-continuous oil refinery plant | |

| Capacity (Ton/Day) | 10-30tpd |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castoroil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil,etc. |

| Main equipment: | Refining reactor, Decolorization reactor, Vibrating filter, Deodorizing tower, Deodorizedoil pump, Centrifugal water pump, Heat conductive oil furnace |

Pictures show of semi- continuous edible oil refinery plant :

Semi- continuous edible oil refinery plant

Fully- continuous edible oil refinery plant introduction :

Specification of Fully- continuous edible oil refinery plant:

| 3. Continuous oil refinery plant | |

| Capacity (Ton/Day) | 30-1000tpd |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castoroil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil,etc. |

| Main equipment: | Washing centrifuge,Vacuum dryer, Decolorization tower, Decolorization oil pump, Platefilter, Deodorization tower, Cooling tower, Thermal oil furnace |

Pictures show of Fully- continuous edible oil refinery plant:

Fully-continuous edible oil refinery plant

We are professional manufacturer of edible oil refinery plant.We provide high quality edible oil refinery plant as well as free and skilled technical guidance! Supply various kinds of cooking oil mill plant solutions for different customer depends on your customized demands. Premium equipment for cooking oil processing machine, cooking oil solvent extraction plant, cooking oil refining machine and so on.