Palm oil extraction plant devices into 3 plants, palm oil pressing plant, palm oil refinery plant, palm oil fractionation plant. As manufacturer of palm oil extraction plant, we can offer whole line or part of palm oil extraction plant for different capacity with turnkey service.

Here we will introduce you palm oil extraction plant in details as follows:

Palm bunches → Sterilizing → Threshing → Crashing → Pressing → Subsidence and filtration → Refiney → fractionation.

Pressing plant of palm oil extraction plant:

|

1. Sterilizing: In general, fresh fruit bunches should be sent into palm oil extraction plant in 24 hours after harvest to prevent palm oil acid value increase caused by fatty enzymes. Palm bunches sterilizing also inactivate fatty enzyme with high temperature to prevent enzyme break palm oil chemical structure. |

|

2.Threshing: The palm fruit proportion is about 60% of the FFB. In this section, we always use rotating drum thresher to separate palm fruit from the bunches. |

|

|

3. Digesting: The purpose of digestion is to destroy the skin of palm fruit, separate the palm pulp and nuts, pound palm pulp and damage the cell structure of palm pulp, which is good for pressing section later. |

|

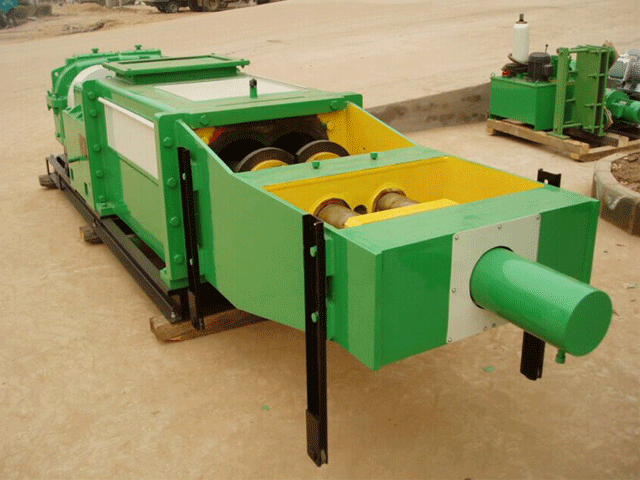

4.Pressing: In palm oil extraction plant, palm oil screw press is common equipment we use, the output of which is mixture of water, oil &residue and presscake (fiber cake). |

|

|

5. Subsidence and filtration: Separate the fiber from the mixture derived from pressing by subsidence and filtration, after continuous subsidence we can separate oil and precipitate. With another filtration and vacuum drying, the oil is just crude palm oil as we say. |

Refinery plant of palm oil extraction plant:

Palm oil refinery plant is similar with other oil plant, devided into 4 parts: degumming, deacidification, decolorization, deodorization.

The only difference comes from capacity; In general, batch type oil refinery plant is utilized in palm oil refinery plant with capacity less than 20TPD; And semi-continuous palm oil refinery plant is suggested to capacity from 20-50TPD; finally continuous palm oil refinery plant is used for capacity above 50TPD.

Of course, this is just an option, not necessarity. Our engineer can help you deisgn whole palm oil refinery plant according to your capacity and requirements.

Palm oil refinery plant

Palm oil refinery plant

Fractionation plant of palm oil extraction plant:

Fractionation plant devides into 3 parts, crystallazing, crystall growing/maturing, and filtration.

After palm oil fractionation plant, palm oil is separated to several parts with different melting points, which can be used in different industrial usages.

Palm oil fractionation plant

Palm oil fractionation plant

We have been specialized in palm oil extraction plant for decades. Our professional engineers can help you design and install palm oil extraction plant according to your capacity and requirements. If you are interested in palm oil extraction plant, please feel free to contact us.