We have been specialized in canola oil extraction plant since 1967. We can offer whole line of canola oil extraction plant with turnkey service, capacity from 10 to 6000TPD . For special capacity, our engineers can help you design and install canola oil extraction plant according to your real conditions.

Canola oil extraction plant starts with rapeseed, with oil content 40%, more or less. Same with other common oilseeds, there're four main sections of canola oil extraction plant, including prepressing/pressing/pretreatment section, solvent extraction section, refinery section and dewaxing/winterization section.

►Pressing/Prepressing of canola oil extraction plant:

Rapeseed → cleaning → softening → flaking → cooking → pressing → pressed canola oil + pressed cake

|

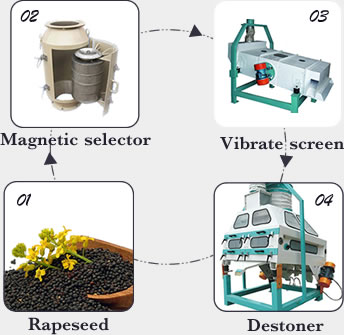

1. Cleaning: Cleaning is the beginning of oilseeds pretreatment, which can influence the final oil quality and machine life time directly. Cleaning section contains magnetic selector, stoning machine, etc. The main function of cleaning is to remove mechanical impurities in rapeseed. |

|

2. Softening: Softening is to adjust the temperature and moisture of rapeseed with steam.Softening adjusts moisture and temperature of oil seeds, softens and increases plasticity of oil seeds. For low oil content oil seeds (soybean, rape seed/canola, cotton seeds, etc), softenning is an essential process for better flaking effect. |

|

|

3. Flaking: Flaking uniforms oil seeds to thin cake, which benefits oil pressing and extraction. Flaking presses oil seeds from granulous to laminar, which brokes cell tissue of oil seeds and creats beneficial condition for cooking. Flaking also makes oil flows out smoothly when pressing or solvent extraction. Flaking roll is common for soybean. |

|

4. Cooking:

Cooking reduces moisture in flakes, which is much easier to press oil out from oil seeds. All these changes makes oil easy to isolate and also enhance crude oil quality. Cooking pot can be used for processing groundnut/peanut, canola seed,cottonseed, sunflower seed,etc. |

|

|

5. Pressing: The final products of this section is just pressed canola oil and pressed oil cake. Pressing/prepressing is to press oil from oil seeds or cakes. In general, there are several oil press machine for this step. Pressing section is mainly for processing high oil content, as groundnut/peanut,sunflower seed, canola seed, cottonseed, corn germ etc. |

►Solvent extraction of canola oil extraction plant:

Pressed cake → extractor → desolventizer toaster → Stripping tower → crude canola oil

Solvent extraction plant derives canola oil from oil seeds at maxium. And to rapessed with high oil content, pressed cake is the material to extract canola oil from.

|

1. Extractor: In extractor, cake is mixed with solvent evenly while oil is sepearated from other ingredients to mix with solvent. Miscella discharged from extractor and into miscella filter, then the leached meal in the miscella tank enter into evaporation system through 1st evaporation feed pump and finally drop-in DTDC out from wet meal drag conveyor. |

|

2. Desolventizer toaster: After extractor, mixture of oil, cake and solvent is separated to oil mixture(mainly oil), and cake mixture(mainly cake). Cake mixture is heated with steam in desolventizer toaster and with further operation we can get pure cake to be used in animal feed. |

|

|

3. Stripping tower/ oil stripper: Oil mixture is heated with steam to get pure oil and solvent is collected to be reused.stripping tower utilizes indirect steam from desolventizer toaster and waste heat from steam-jet pump as heat source, which saves energy, reduces space for condenser and needs less investment. |

►Refinery section of canola oil extraction plant:

Canola oil refinery plant includes 5 parts, degumming, deacidification, decolorization, deodorization, dewaxing. The former 4 parts are similar with general oil refinery plant while dewaxing is similar with rice bran oil refinery plant because the wax content of canola oil is rather high.

Rapeseed oil refinery plant

Rapeseed oil refinery plant

We can offer turnkey service of canola oil extraction plant including design, installation, trail run, etc. Our professional engineers can help you design and install canola oil extraction plant according to your capacity and requirements. If you want to know more about canola oil extraction plant, please feel free to contact us.