Henan Doing Company is professional in peanut oil extraction plant design, installation, commissioning, technical training and so on. We can provide you the turn key project of the whole peanut oil extraction plant from 20 to 2000TPD. Here, I will introduce peanut oil extraction plant that uses solvent extraction method.

In order to improve oil yield rate and get high quality peanut oil, the peanut oil extraction plant should consist following processes: peanut kernel pretreatment, peanut oil prepressing, peanut oil solvent extraction and crude peanut oil refining.

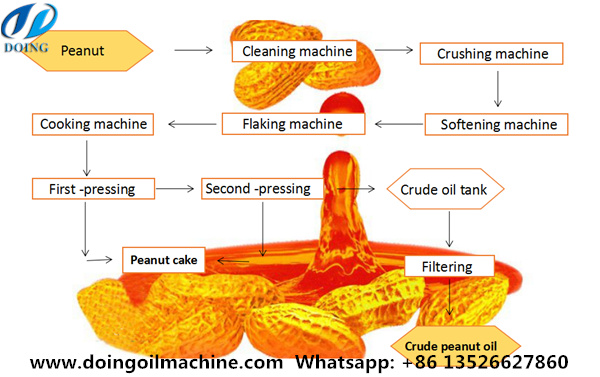

Ⅰ、Pretreatment section of the peanut oil extraction plant

Pretreatment section is to remove the impurities in the peanut kernels and change its structural characteristics, in order to make it suit the requirements of the peanut oil extraction process. And the oil content of peanut kernel reaches 44%-45%, not suitable for direct solvent extraction, so prepressing section is necessary in peanut oil extraction plant.

Peanut oil pretreatment and pressing process flow chart:

Peanut oil pretreatment and pressing process flow chart

Peanut oil pretreatment and pressing process flow chart

Peanut oil pretreatment and pre-pressing machine introduction:

|

|

1> Cleaning: Cleaning machines includes magnetic separator, cleaning seive, winnowing machine, etc. They can remove mechanical impurities such as solid, iron impurities, sick seeds, etc. Cleaning section prevents the following equipment from damage, and increases oil yield. So cleaning is an essential part in peanut oil extraction plant. |

|

|

2> Husking: The main ingredients of peanut shells is fiber, wich would hinder peanut oil extraction. Husking separates hulls from peanuts to improve the oil yielding rate, crude oil quality and meal quality. |

|

|

3> Crushing: Peanut kernel is big in size; crushing machine/crusher breaks peanut kernel to smaller pieces to impove pressing effect. |

|

|

4> Flaking: Flaking damages oil cells, increases oil surface, and shortens the oil outflowing distance, which benefits oil extraction and impoves cooking efficiency. |

|

|

5> Cooking: This process can improve prepressing oil yield rate and meal quality, and also adjust the moisture, temperature and plasticity of the flake. |

|

|

6> Prepressing: To squeeze out part of peanut oil, and improve extracting efficiency. |

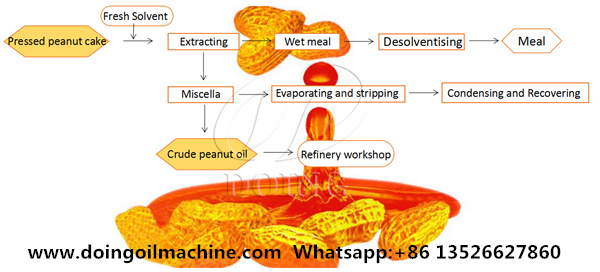

Ⅱ、Extraction section of the sunflower oil extraction plant

Extraction section is to extract peanut oil by suitable organic solvent, this method can get the highest oil yield rate. After peanut oil solvent extraction plant , the residual oil rate in cake is less than 1%.

Peanut oil solvent extraction process flow chart are as follows:

Peanut oil solvent extraction process flow chart

Peanut oil solvent extraction process flow chart

Peanut oil solvent extraction process introduction:

1>Extraction:

To extract the oil in the cake by solvent, the general solvent is 6# extraction solvent oil or commercial hexane.

To remove and recover the solvent in the meal; Dry and cool down the meal at the same time.

Heating the the miscella by indirect steam, so that can vaporize the solvent and concentrate the miscella.

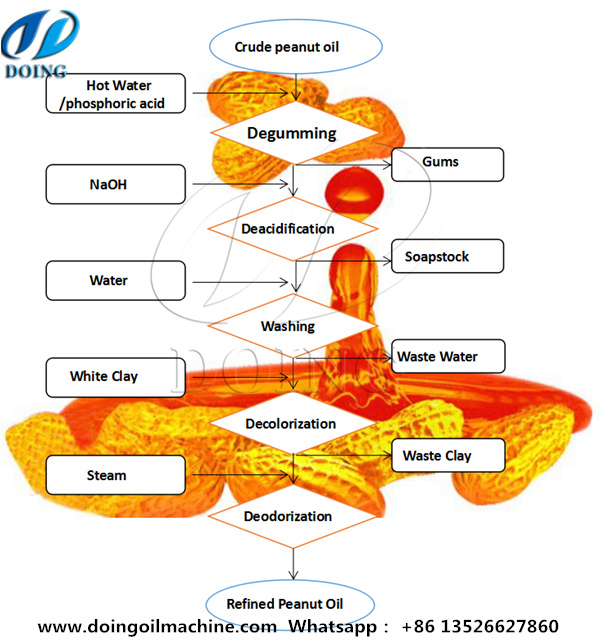

Ⅲ、Refining section of peanut oil extraction plant

Refining section is to remove the impurities in the crude peanut oil and improve peanut oil quality. The whole peanut oil refining process includes degumming process, deacidification process, decolorization process and deodorization process. After peanut oil refinery process, The refined oil has high quality and is good for long time storage.

Peanut oil refining process are as follows:

Peanut oil refinery process flow chart

Peanut oil refinery process flow chart

Main process of peanut oil refinery plant:

1> Degumming: Degumming removes gums as preparation for subsequent refining processes.

2> Deacidification: Deacidification removes FFA (free fatty acid) in crude oil.

3> Decolorization: Decolorization removes pigments in crude oil by adding white clay, which can improve the oil quality.

4> Deodorization: Deodorization removes odor in crude oil, which can improve the flavor, stability, color and quality of the oil.

Peanut oil refinery plant photos:

|

|

|

In general, there're 3 types of peanut oil refinery workshop, batch, semi-continuous, and continuous refinery workshop.

As manufacturer of peanut oil extraction plant, we can offer whole line or parts of peanut oil extraction plant with general capacity from 10TPD to 2000TPD. For special capacity, our engineers can also help you design and install workshop according to your capacity and requirements.