Semi-continuous edible oil refinery plant

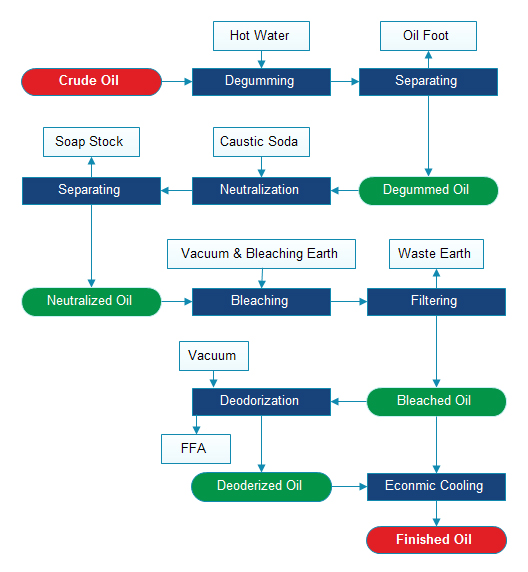

Semi-continuous edible oil refinery is a step by step process. The entire semi-continuous edible oil refinery process comprises degumming/neutralization, bleaching, deodorization, and winterization.Semi-continuous edible oil refinery used to refine almost all kinds of oil extracted from oil seeds like sunflower seeds, linseeds, groundnuts, sesame seeds, and mustard seeds, etc.

Process flow chart of edible oil refinery plant

Features of semi-continuous edible oil refinery plant:

1.The effect is good. The semi-continuous edible oil refinery process can be adjusted according to the situation of oil and requirement of the final oil.

2.Suitable operation and advanced semi-continuous edible oil refinery reduce the oil consumption.

3.In the decolorization part, the oil and white clay is mixed in the vacuum. This avoid the air influence. This can reduce the consumption of white clay.

4.The white clay dosing machine can add the clay exactly.

5. Whole of the deodorization is going under the vacuum. The vacuum can avoid the oxidation of oil and improve the quality of oil.

6. The stripping and distillation are used to keep the taste and stabilize of the final oil.

Semi-continuous edible oil refinery plant

Main equipments of semi-continuous edible oil refinery plant:

Refining pot: It also be called degumming and deacidification pot during semi-continuous edible oil refinery. Under the 60-70℃ temperature, the alkali is used to react with the acid. Then the acid value is reduced. The phospholipid is also separated from the oil and go to the nigre pot.

Decolorization pot: It’s also called decolorization and dehydration pot. The high temperature and vacuum helps to move the water in the oil. The white clay is absorbed in the decolorization pot by the vacuum. After mixing, the filter helps to separate the white clay from the oil.

Deodorization tower (whole stainless steel): The decolorized oil is heated by the screw heat exchanger and steam heater. When the temperature is got 240-260℃, it enter the deodorization tower. The deodorization tower is combined type. The top of the tower is filler. The function of the filler is to move the free fatty acid in the oil and move the bad smell of the oil. The bottom of the tower is plate tower. It’s used to reduce the peroxide value of the oil. The final oil that coming out from the tower will exchange the heat with the decolorized oil. Then the temperature of the final oil is reduced to 80-85℃ by the cooler. After adding the antioxidant, the oil is kept under 50℃. The free fatty acid is collected by the catcher.

The second floor of semi-continuous edible oil refinery plant

The second floor of semi-continuous edible oil refinery plant