Compared with pressing, solvent extraction has higher oil yeild and lower labor cost with better work environment and better-quality cake.

There are 2 tupes of solvent extraction, direct solvent extraction and pre-pressing extraction. Direct solvent extraction is always used for low-oil-content oil seeds, while pre-pressing extraction is used for high-oil-content oil seeds.

1. Oil extraction:

Oil extraction is to extract oil from oil oil base or pre-pressed cake to oil mixture and meal.

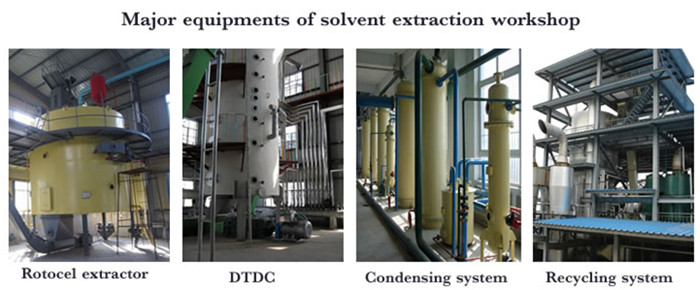

The major equipment of this section is extractor, and extraction pot is always used in batch extraction while continuous extraction uses loop type extractor, rotocel extractor, crawler type extractor, etc.

2. Desolventizer toaster:

Meal from extractor consists of 25-35% solvent. And in order to recycle solvent and get better-quality meal, wet meal drying is necessary.

And high bed desolventizer toaster is always used in pre-pressed leaching meal, while DTDC desolventizer toaster is always used for direct extraction meal.

3. Oil stripping tower/ oil stripper:

Oil mixture consists meal powder, solvent and oil. This step is to seperate these 3 indreginents by filtration, evaporation, and stripping.

The major equipments for this section include filter, cyclone hydraulic separators, evaporator, stripping tower, etc.

We can help you design or choose the most suitable equipment according to your capacity.

4. Solvent vapor condensation and recovery:

Mixed vapor from desolventizer toaster, evaporator, and stripping tower should first be condensed to liquid by condensers, and then seperate solvent and water by water separator, and finally get recycled solvent to reuse in extraction.

We can offer whole line of solvent extraction for different capacity. If you want to know more about solvent extraction workshop, please feel free to contact us.

learn more