2.Collect your oil. You can spend the extra money and buy new cooking oil or you can find a restaurant and ask them if you can take their used cooking oil off their hands. Used cooking oil will have a darker color to it and will most likely have chunks of your favorite fried foods floating around. You will need to get rid of these before making biodiesel homebrew.

Collect your oil

3.Remove the chunks. Filtering your used cooking oil will eliminate the chunks of food and other particles before your begin your biodiesel homebrew process. Larger chunks can contain water and can mess up your biodiesel reaction.

Remove the chunks

·As you pour out your used cooking oil let it completely run through the filter. The filter doesn't need to be too fine. A paint strainer or window screen will adequately remove the particles that are large enough to affect the biodiesel reaction.

·You will notice large chunks of fried mystery food collecting in the filter. This filtration process can be fairly quick, but you can let the filtered biodiesel settle anywhere from a couple of hours to a couple of days to let the smaller particles settle out.

·Smaller suspended particles should also be allowed to settle so they doesn't attach to your heating element and muck up your processor.

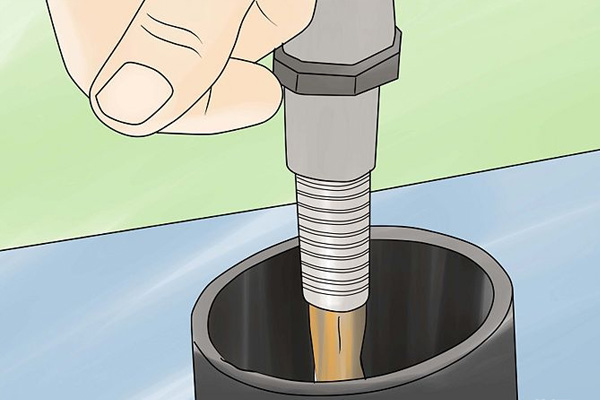

·Once settling is complete, begin transferring your used cooking oil to the reaction tank on your processor.

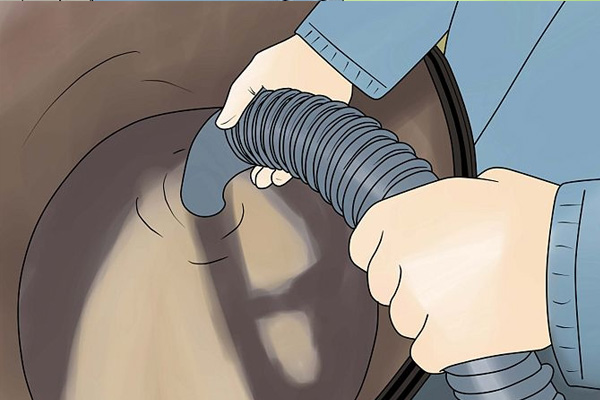

4.Transfer to the tank. Take the hose that connects the collection barrel to the reaction tank on your biodiesel compressor and connect it to the pump.

Transfer to the tank

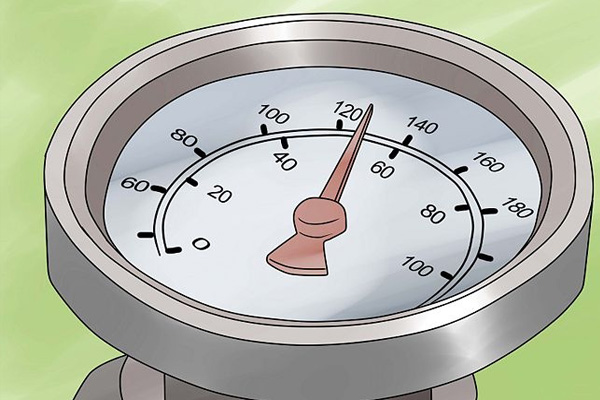

5.Heat it up. As your cooking oil makes its way into the reaction tank, you need to heat up the oil to about 120 or 130 degrees Fahrenheit. During the heating process, the pump on your compressor will circulate the oil. Circulating and heating the oil distributes the heat and prevents the oil from getting too hot right near the heating element. This heating and circulation process will take approximately one to four hours. Factors that affect heating time:

Heat it up

6.Begin your biodiesel fuel process. You have just finished properly filtering your used cooking oil. By choosing to use an alternative fuel, you are helping to cut down on CO2 emissions, cut dependence on oil imports and saved yourself some money.

Begin your biodiesel fuel process