The vegetable oil we eat everyday is extracted by two mature technologies. One is physical pressing way, the other is solvent extraction way. Solvent extraction way means use solvent which can dissolve the oil in the oil seeds, while other parts of the oil seeds is not influenced. It is a massive industrial production process, by this way; the oil residue usually is 1%. Large capacity factory if they adopt simple pressing way to extract oil, the oil residue quantity would be big; the oil loss would be large too. Solvent extraction way is more suitable to factory with capacity of more than 30 tons per day.

Edible oil solvent extraction plant

The process for edible oil solvent extraction way usually is: 1, to get mixture of crude oil and solvent. 2, separate the crude oil from the solvent. 3, separate the solvent from the meal. 4, to process the solvent for recycle use.

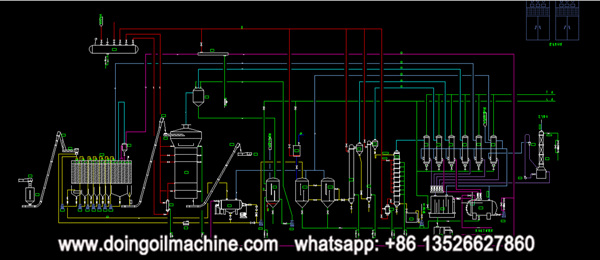

Edible oil solvent extraction process flow chart

The machine involves in edible oil solvent extarction plant mainly is solvent extractors, Evaporators and stripper steaming tower, DTDC to separate the solvent from the meal and solvent recycle using system.

Then, the crude oil could be sent to oil refinery plant and the meal after drying could be packed for sale.