Doing series oil filter press machine is plate type oil filter machine which is mainly being used for separating solids and liquids in the oil production plants for edible or vegetable oils. This model plate and frame type oil filter press machine is suitable for filter crude oil and refined oil, and it is also could be applied to filter bleaching oil in the oil refining plants.

Doing Company supplies a wide range of oil filter press machines designed to give maximum filtration efficiency, longer service life and less maintenance. The oil filter presses are available in different sizes and various capacities. We can also provide oil filter presses to custom specifications.

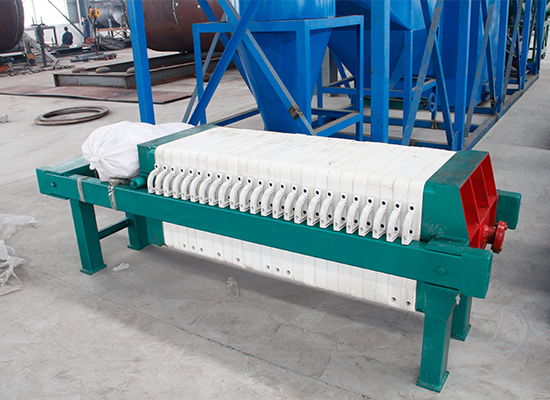

Plate and frame type oil filter press machine

Plate and frame type oil filter press machine, the typical intermittent pressed filter equipment, applies to solid-liquid separation of all suspension. The filter chamber is formed by filter boards and filter frames or filter boards rows (box-type), under the function of conveying pump, it press the suspension liquid into filter rooms and through filter intermediaries (filter cloth, filter paper and filter membrane) to separate solid and liquid. What is more, the box-type filter boards can be classified into common boards and diaphragm boards. The filter can be used wildly in petroleum, chemical industry, medicine, sugar, metallurgy, food, china, starch, coal washing, dye, and paint as well as sewage treatment in all industries.

Main features of the plate and frame type oil filter press machine:

1. Application in Mining, Food, Industrial Chemical, Pharmaceutical, Oil, Solid-liquid Separation Industries.Detail as: Ceramic, Gelatin, Edible Oil, Chemicals, Food Processing, Pharmaceuticals, Leather Tanneries, Sewage Treatment Plants, Effuluent Treatment Plants, Sugar, Fertilizers,Petro Chemcials.

2.Structure is made of high quality carbon steel. Plate and frame type oil filter press machine adopts automatic welding, solder side is flat, weld-joint is solid and durable, it can perfectly avoid distortion.

3.Main beam is processed by high speed centrifugal sand blasting to remove rust and iron oxide scale, then painted by epoxy micaceous iron primer to get better rustproof and corrosion resistance effect.

Plate and frame type oil filter press machine operation steps as follows :

1. Closing of the press: as the filter is completely empty, the moving head activated by the jacks calmps the plates.

2. Filling: For sludge having good filter ability it is best to fill the filter very quickly so as to avoid the formation of a cake in the first chamber before the last ones have been filled.

3. Filtration: When the filtration pump has stopped, the filtrate circuits and central duct, which is still filled with liquid sludge, are purged by compressed air.

4. Filter opening: The moving head is drawn back to disengage the first filtration chamber. The cake falls has a result of his own weight. A mechanised system pulls out the plates one by one.

5. Washing: Washing of clothes should be carried out every 15-30 processing oprations. For mid- or large units this take place on press using water sprayers at very high pressure (80-100 bar).