The quality and design of palm oil production line is the key to the quality of palm oil and also the crucial to the success of your palm oil business.If you are planning for starting a palm oil mill plant, you may interested to know about palm oil production line and cost.We supply complete set of palm oil production line for diffrent customer.

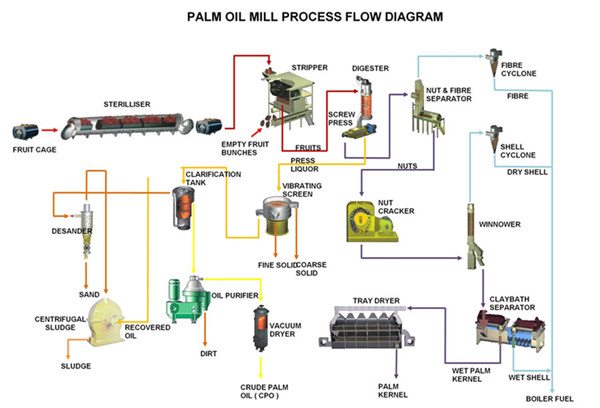

The palm oil is contained in palm pulp, the pulp is high moisture content and rich lipase. Usually we adopt the method of press to produce it, and this technology is very mature.80-120tph palm oil production line usually used in large scale palm oil mill plant.Complete set palm oil production line include a series of process,such as Raw Materials Storage Section,Sterilization Section, Threshing Section,Digesting&Pressing Section,Oil Clarification Section,Palm Kernel Recovery Section and so on.

Basic information of palm fruits:

Oil palm belongs to palmaceous plant; It is mainly distributed in tropic area and some sub-tropic areas; It is one of the most important tropic oil seed plants in the world . The oil rate in oil palm is very high: generally 46~50% in the fresh pulp , and 50~55% in palm kernel.And the palm fruit is the raw materials of palm oil production line.

The process of palm oil production process:

Palm oil production process flow chart

Raw Materials Storage Section :

Collecting the ripe fresh palm fruit bunches from the plantation and transported by trucks is the first step of palm oil production line, then pour the FFB into the discharge door after weighed by weighbridge.

The discharge door has discharging channels, the upper and lower switches of the iron gate are controlled by pneumatic control system consists of air compressor and pneumatic control devices. Start the control valve to open the gate of the discharge door, then the palm fruits will fall into the fruit basket car or conveyor.

Sterilization Section of :

Sterilization is a main process of palm oil production line that injecting 300KPa direct steam into to sterilizer to boil the palm fruit for about 60 mins.The purpose is to break the enzymes in fruit, and to avoid the increasing of the FFA content in oil. At the meanwhile, the high temperature will makes the fruits soften, it is easy for fruit threshing and kernel cracking. Also reducing the damage of kernel.

Threshing Section :

Oil palm fruit accounted for about 60% of the whole fruit bunch, The purpose of threshing is to separate the palm fruit from the FFB. The drum type thresher is the common machine used to separate the fruit. There is a horizontal turning machine inside of the threshing machine. The separated oil palm fruit is sent to the pressing section. Empty palm fruit bunches are transport to the yard from the other side of the thresher drum, or transported from the factory as palm plantation slipcover to recycling use, or burning directly as fertilizer for agricultural land.

Digesting&Pressing Section :

Digesting is for breaking off the palm fruit, and with high temperature to soften the fruit and kills the bacteria. Sterilizing, threshing and digesting all important for palm oil production line which help increase the palm fruit oil yield.

Inside the digester, there are baffles and stirring arms, under the driving of the top motor, baffles break off the palm fruit and heat the palm fruit, so it can pressing oil easily.

Pressing machine use hydraulic control system to adjust spacing between screws. So it is suitable for various palm fruit species and guarantee the oil yield. After pressing, the crude palm oil needs to be purified, the kernel and fiber impurities can be processed by further separation from the pressed cake. After drying, the kernel is stored for deep process, and the separated fiber and shell are used as the boiler fuel for providing steam.

Palm oil pressing machine is suitable for pressing palm oil from palm fruit

Oil Clarification Section :

Advantages: Use latest technology; Guarantee the oil quality; Reduce machine investment; Lower oil loss.

The purified palm oil can be directly sold or deeply refining. After clarification, the industrial sewage will be sent into effluent pond. Then the residual sludge can be used as the fertilizer. The whole process is high automatic, environment friendly and energy- saving.

Palm Kernel Recovery Section :

Pressed cake is transported into the fiber separation air net and nut polishing drum for fiber&nut separating. There are some fiber covering outside palm nut. In order to get palm kernel, we should remove the fiber and shell first.

The cracked palm nut adopts separating column system and special hydrocyclone equipment to separate palm kernel and shell according to their different density. So it has high separation rate.

After separation, the shell is used as boiler fuel; the moisture content of separation kernel is less than 7% after drying through the hot air. Dried kernel can be sent to kernel storage silo or warehouse for storage.