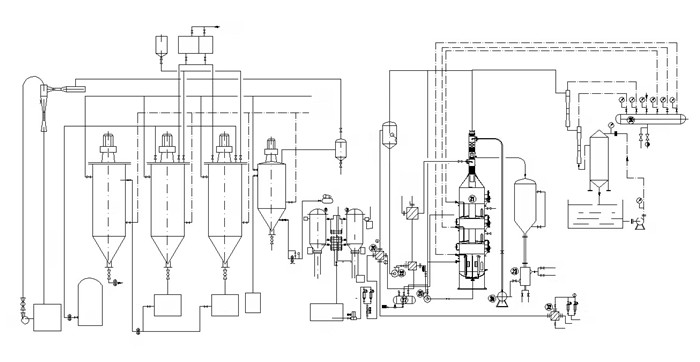

Function of each process in edible oil refinery machinery:

Degumming :Adding water and little P-acid to combined with the impurities and then remove the gum.

Deacidification :Using alkali like (NaOH) to neutralize FFA in oil, during edible oil refinery machinery it will get nigre, then separating it from the oil.

Decolorization: using the active clay to absorb the pigment in oil, then separating the waste clay. You will get light yellow color oil.

Deodorization : the crude oil smells not good, it will affect of oil storage and price. So during edible oil refinery machinery,we usually use the direct steam to take away odors. At the meanwhile, it can also remove water and FFA from oil.

winterization/fractionation :Oil is consist of triacylglycerol with different melting point.under a specified temperature,there will has some solid part come out from oil,it will affect the appearance and price.winterization and fractionation is to remove or separate the solid part to get fully liquid edible oil.it is suitable for some kinds of vegetable oil,like rice bran oil,sunflower oil,corn germ oil,palm oil etc.

Different types of edible oil refinery machinery:

Mainly there are two methods of refining:chemical method and physical method.different demand we can devide the edible oil refinery machinery into three types:batch type,semi-continuous type,fully-continuous type.

Different types of edible oil refinery machinery

Batch type edible oil refinery machinery :the process is to refine the oil batch by batch,suitable for small capacity like 1-2-3-5-10TPD.

Semi-continuous type edible oil refinery machinery:part of the edible refinery machinery is batch type and left part is continuous type.this is cost-effective and save labor.suitable for medium capacity like 10-30TPD

Continuous type edible oil refinery machinery:the whole refinery process is fully continuous,no need much human operating.suitable for big capacity above 30TPD