Home > News > Industry News Rice bran oil knowledge and rice bran oil production machine introduction

Home > News > Industry News Rice bran oil knowledge and rice bran oil production machine introduction

In the rice bran oil production process, after the rice is milled from the white rice production, rice bran quickly becomes rancid and is unfit for human consumption. And generally, the raw rice bran was mostly sold as animal feed. But there has 15-20% oil content in the rice bran, the rice bran oil can be human consumption, The paddy production's amount is 37% of total grain output in the world, in the rice bran oil production process of paddy rice to be white rice, the shell and 10% testa and embryo will be removed.

Rice bran is made of testa and embryo, one of the main byproduct, research and the data show that the rice bran is rich in various nutrients and the physiological active substances.Refined rice bran oil is light yellow or brown color liquid oil.Rice bran oil is extracted from rice skin and germ which concentrate the most nutrition.And rice bran oil is of rich nutrition which contains 80% UFA (unsaturated fatty acid). The rate of SFA(saturated fatty acid), MUFA(monounsaturated fatty acid ), PUFA(polyunsaturated fatty acid) is 1:2.1:1.8

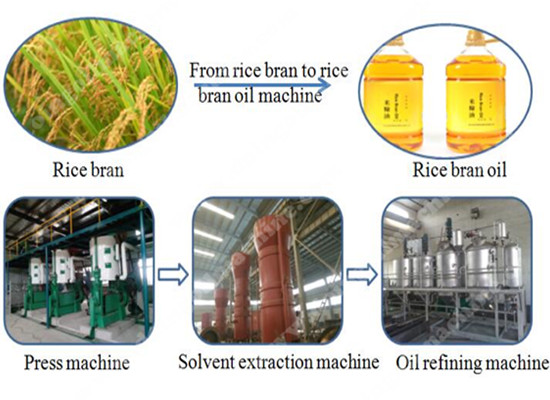

Rice bran oil production process machinery

There are three main sections to make rice bran oil in the rice bran oil production process:

Rice bran pretreatment section

Rice bran oil extraction section

Rice bran oil refinery and dewaxing section

Pretreatment plant make the rice bran into pellet for easy and max oil yield.Send the pretreated rice bran into solvent extraction plant,use the solvent (normal hexane) to absorb the oil from rice bran, and then the machines separate the solvent from the oil, the solvent used for recycling and the crude rice bran oil goes into refining plant. After extraction, the residual oil in rice bran can be lower than 0.8%.Crude rice bran oil refining and dewaxing for high quality oil.