Home > FAQ What is the difference between pressing and solvent extraction methods for extracting soybean oil? How do I choose the right extraction method?

Home > FAQ What is the difference between pressing and solvent extraction methods for extracting soybean oil? How do I choose the right extraction method?

In the soybean oil extraction industry, choosing the right extraction method is crucial for maximizing oil yield and maintaining oil quality. The two primary methods—pressing and solvent extraction—each has difference processes, advantages and considerations. This article aims to clarify these differences, helping clients make informed decisions based on their specific needs.

The method involves a series of steps aimed at extracting soybean oil by mechanically pressing soybeans. The specific steps are as follows:

(1) Cleaning: Some cleaning machines are used to remove impurities such as dirt, stones, foreign matter and other impurities from soybeans.

(2) Crushing: Using a crushing machine to break the soybeans into small pieces to facilitate soybean oil extraction. At the same time, the surface area of the soybeans is increased, which is conducive to the transfer of temperature and moisture during the subsequent softening of the soybeans, ensuring the softening effect.

(3) Softening: Adjusting the temperature and moisture to make soybeans have appropriate elasticity and plasticity.

(4) Flaking: The roller-type flaking machine is used to press soybeans from granules into thin flakes. In addition, the cell structure inside the soybean is destroyed, the oil path is shortened, and favorable conditions are provided for the production of soybean oil by pressing.

(5) Roasting: Heating the crushed soybeans to enhance oil release and deactivate anti-nutritional factors.

(6) Pressing: Utilizing mechanical soybean oil press machine to extract soybean oil from the pre-treated soybeans.

(7) Filtering: Removing residue from crude soybean oil.

Soybean oil pressing production line

Soybean oil pressing production line

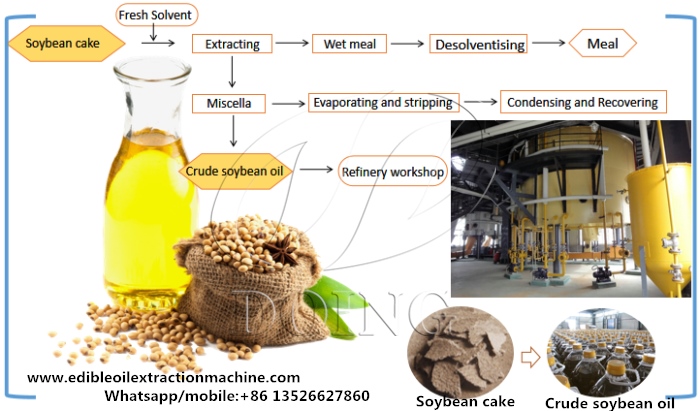

This method employs a chemical solvent (typically n-hexan) to dissolve and extract the oil from the soybean cake, allowing for a higher extraction rates. The specific steps are as follows:

(1) Solvent extraction section: Soaking the soybean cake in the solvent to dissolve the oil.

(2) Mixed oil evaporation and gas stripping: The mixed oil solution is evaporated twice. After evaporation, the mixed oil solution needs to be stripped in a stripping tower to further remove the residual solvent and obtain pure crude soybean oil.

(3) Wet meal desolventization: The residual solvent in the soybean cake is removed by D.T.D.C system.

(4) Solvent recovery: The solvent vapor is condensed into liquid solvent by using a condenser for recovery.

Soybean oil solvent extraction machine and production process

Soybean oil solvent extraction machine and production process

Pressing: This method typically results in a higher residual oil rate, generally about 6%-7%.

Solvent extraction: This method can achieve less than 1% residual oil content, making it the preferred method for maximizing soybean oil extraction efficiency.

Pressing: Produces a more natural soybean oil with better flavor and fewer chemical residues. This method is often favored for premium products.

Solvent extraction: While it yields more soybean oil, it may result in soybean oil with trace solvents and lower sensory qualities. Additional refining steps are usually necessary.

The picture of soybean and soybean oil

The picture of soybean and soybean oil

Pressing: Generally involves lower initial investment and operational costs, making it suitable for small to medium-scale operations.

Solvent extraction: Requires a higher initial investment in soybean oil extraction machines and ongoing solvent costs, making it more viable for large-scale operations where high volume is necessary. In this regard, the soybean oil extraction machine engineer of Henan Glory Company recommends that you can choose the solvent extraction method for extracting soybean oil when your production capacity is above 30tpd. In other words, if your production capacity is small, it is not cost-effective to buy soybean oil extraction machines.

Pressing: This method is typically considered more environmentally friendly, as it does not involve chemical solvents and produces less waste.

Solvent extraction: Although efficient, it involves the use of chemicals that require careful handling and disposal, raising environmental concerns.

When deciding between pressing and solvent extraction methods for extracting soybean oil, clients should consider the following aspects:

1) Production Scale: For large-scale operations, solvent extraction method might be more suitable, while smaller producers may benefit from the simplicity of pressing method.

2) Target Market: If the focus is on premium natural soybean oil, pressing method may be the better choice.

3) Cost Structure: Analyze the long-term costs and benefits associated with each method based on expected oil yield and quality.

In conclusion, understanding the differences between pressing and solvent extraction methods for extracting soybean oil is essential for making an informed decision in soybean oil extraction. By considering factors such as oil yield, quality, cost and environmental impact, etc, clients can choose the right extraction method that aligns best with their soybean oil extraction goals. If you have any questions about soybean oil extraction, welcome to reach out to us for further information or inquiries about our soybean oil extraction solutions. Let us help you optimize your soybean oil extraction for quality and efficiency!