Before starting cooking oil pressing business, in addition to preparing licenses and other certificates, the site also needs to be carefully considered. Different oil presses with different processing capacity also need different equipment covering different areas. Next, I will introduce the cooking oil manufacturing plant area required for common processing capacity.

1.Capacity of below 10tpd

Press section: a wok, an oil press, a filter and two strainers.

A wok is used to regulate moisture and temperature. Oil press can extract the oil in the oil, so as to get the crude oil and cake. The filter helps to filter out fine impurities and moisture, resulting in a cleaner cooking oil. The recommended cooking oil manufacturing plant area is L10m*W6m*H6m.

Small scale cooking oil production line

Small scale cooking oil production line

Refining section: The maximum capacity that can be matched is 5tpd, including alkali smelting pot, decolorizing pot, deodorizing pot, etc. The recommended cooking oil manufacturing plant area is L15m*W8m*H7m.

2.Capacity of 10-50tpd

Press section:

Small scale cooking oil manufacturing plant

Small scale cooking oil manufacturing plant

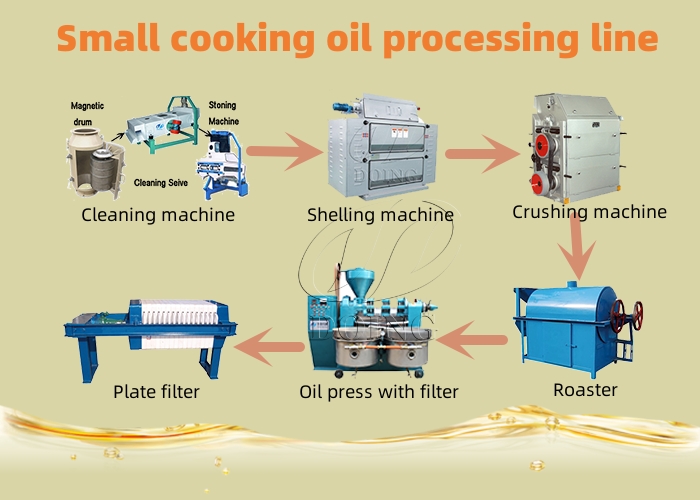

1. Shell - Clean

The shell peeling machine is used to remove the shell of the oilseeds, and the cleaning is the use of magnetic separator, cleaning screen and stone machine to remove impurities in the oilseeds.

2. Crushing

Using a crusher will reduce the particles of the oilseeds and increase the surface area of the oilseeds, so that the speed and output of the oil will increase.

3. Flaking

The function of the rolling is to press the oilseeds into sheets so that the crude cooking oil can flow out of the oil more easily.

4. Cooking

The equipment used for cooking is roaster, which can adjust the temperature, humidity and internal structure of the oilseeds through cooking, so that the oil can reach a good state before pre-pressing, which can improve the effect of pre-pressing.

5. Pressing

Commonly used equipment is the screw oil press, by squeezing the screw to press all kinds of crude cooking oil.

6. Filtering

Filter the fine impurities and moisture in the crude cooking oil, so that the crude cooking oil storage time is longer.

Recommended cooking oil manufacturing plant area: L38m*W13m*H8m

Refining section: The maximum processing capacity that can be matched is 20tpd. The recommended area of the refining workshop is L30m*W8m*H8m.

Cooking oil refining machine photo

Cooking oil refining machine photo

According to different raw materials and processes, the required plant area is very different, more than 50tpd processing capacity needs to find a professional engineer design solutions. Henan Glory Company is a collection of consulting, research and development, production, manufacturing, installation and after-sales as one of the scientific and technological manufacturing industry, not only has a modern workshop, as well as an independent technical research and development team, has obtained more than 30 patents. For more information on pressing machine, solvent extrcaction machine and refining machine of edible oils, please consult Henan Glory Company.