The oil content of sunflower seed is 40-60%. Some kind need move the shell of the sunflower seed, while some kind don’t. According to actual situation, we can design a most suitable line for each customer. The main function of the sunflower seed pretreatment is to improve the sunflower seed quality as much as possible, and helps to get most oil from the sunflower seed.

The sunflower seed oil yield is 40-60%. So it is better to pre-press first. And then send the raw embryos to the extractor.

Sunflower pretreatment and press machine of sunflower seed oil processing machine

The usual sunflower seed pretreatment/press process as follows:

Raw material → Cleaning screen → Stone separator → Sheller → Flaker → Cooker → Pre-press → crude sunflower oil

Sunflower cake →Oil solvent extraction workshop→Oil refining workshop→Refined sunflower oil

Sunflower oil press machine

The crude sunflower oil from pre-press index:

|

moisture and volatile matter(%) |

≤0.20 |

|

insoluble impurity |

≤0.20 |

|

acid value |

≤4.0 |

|

peroxide value |

≤7.5 |

|

preserve the original smell |

no strong smells |

Features of our sunflower seeds pretreatment technology:

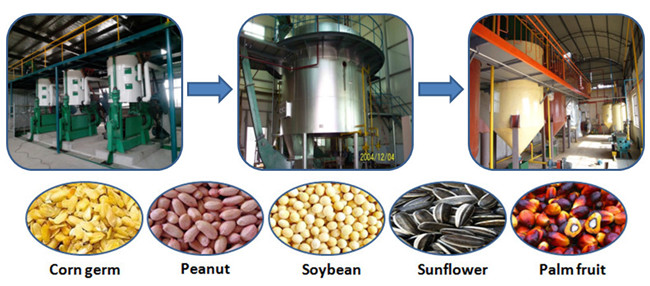

1. Different combinations of process can process various oil plants in one workshop.

2. Use special intensified pretreatment technology for aroma sunflower oil to make it more aroma.

3. Adopt advanced and reliable shelling technology to meet higher requirements for protein content in meal.

4. Extrusion treatment is used for raw materials with hard extraction, large-sized powder, and large capacity, which can reduce residual oil and solvent consumption, and increase the capacity by 50-80%.

5. The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

After the sunflower seed pretreatment/press equipment, the cake also can be extracted oil by solvent way or refined the oil to the best quality.