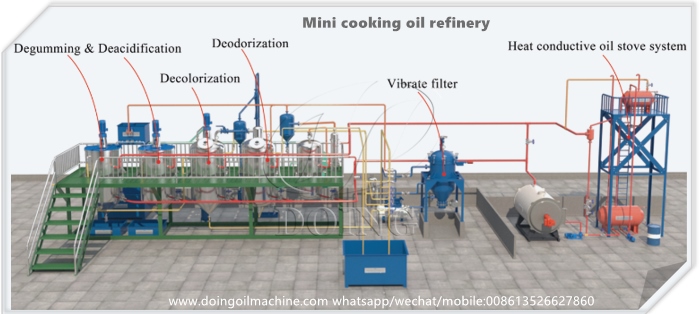

To set up a cooking oil refining plant, a set of cooking oil refining machine is required, which consists of different parts: degumming, deacidification, decolorization, deodorization, filter, heat conducting oil furnace, etc. If you plan to set up a cooking oil refining plant, firstly you should know that the cooking oil refining machine has three types based on the continuous types of machines, and then decide to choose which type of cooking oil refining machine.

1.Batch type cooking oil refining machine

Batch type cooking oil refining machine, also called small cooking oil refining machine, can be designed into 1tpd, 2tpd, 5tpd, 10tpd, 20tpd input capacity. Batch type cooking oil refining machine is easy operation and low investment, very suitable for who want to build a small scale cooking oil refining plant. Because it is batch type, it need workers to operate after each step is finished.

Batch type cooking oil refining machine 3D picture

Batch type cooking oil refining machine 3D picture

2.Semi-continuous cooking oil refining machine

Semi-continuous cooking oil refining machine can be designed into 10tpd, 15tpd, 20tpd, 30tpd, 50tpd input capacity. It combines the batch type and continuous cooking oil machine together, needs workers to operate in degumming and deacidification processes, but can automatically work in decolorization and deodorization processes. About the investment cost, because semi-continuous cooking oil refining machine uses continuous type of decolorization and deodorization tower, the investment cost will be higher than batch type cooking oil refining machine.

Semi-continuous cooking oil refining machine

Semi-continuous cooking oil refining machine

3.Full-continous cooking oil refining machine

Full-continous cooking oil refining machine can be designed into 30tpd, 50tpd, 100tpd, 200tpd, 300tpd, 500tpd, 600tpd input capacity. It doesn't need workers to operate, and all the processes are automatic, high production efficiency, good effect of refining and being able to 24-hours work continuously. As all the processes are all automatic, and the auxiliary equipment between main equipment are the most, the investment cost of full-continous cooking oil refining machine is also the highest.

Full-continuous cooking oil refining machine

Full-continuous cooking oil refining machine

Which kind of cooking oil refining machine you choose is decided by your budget, the quality of crude oil, the requirement of product oil, etc. Except for providing different types of cooking oil refining machine, Henan Doing Company can also provide you with turn-key project service, which includes plant design, process design, machine design, machine manufacturing, installation, commissioning, and worker training.