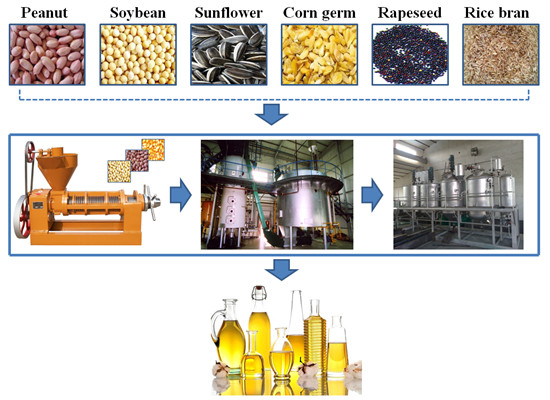

We are professional Soybean Oil Mill Plant manufacturer and exporter. We can offer different capacity Soybean Oil Mill Plant.These Soybean Oil Mill Plants are used for extracting edible oils from soybean. We made Soybean Oil Mill Plant by employing optimum grade materials and modern technology at our state of the art machining facility. We can also customize these plants as per the needs of the clients.

Complete set soybena oil mill plant

Complete set soybena oil mill plant

Features of Soybean Oil Mill Plant:

1. High oil yeild & low waste

2. Stable performance

3. Unique design for each customer

4. Newest technology and automatic

Further Details of Soybean Oil Mill Plant:

The whole Soybean Oil Mill Plant includes soybean pre-pressing workshop, solvent extraction workshop and crude soybean oil refinery machine . In order to let more people have a good understanding , at here, we will introduce the palm oil mil process to you.

1.Soyaben pre-pressing workshop

soybean → magnetic box → cleaning → crushing →softening→ flaking → cooking → oil prepressing → to extraction workshop

What machines are used in soybean oil mill plant? Please read on, you will find the answer:

1) Soyabean Oil Seed Cleaning Machine

2) Soyabean Oil Seed Crushing Machine

3) Soyabean Oil Seed Softening Machine

4) Soyabean Oil Seed Flaking Machine

5) Soyabean Oil Seed Expelling Machine

6) Soyabean Oi Filter Machine

Soybean oil pretreatment machine photos

Soybean oil pretreatment machine photos

2.Solvent extraction of Soybean Oil Mill Plant:

Soybean oil solvent extraction plant is the main equipment in soybean oil production process. The soybean oil solvent extraction plant is designed to extract oil directly from soybean cake. After soybean oil solvent extraction plant, the oil resdual rate in cake is less than 1%.

Soybean oil solvent extraction process flow chart:

solvent→extractor → mixed oil → 1st and 2nd evaporation → stripping tower → crude soybean oil

Wet meal → DTDC toaster → soybean cake

Soybean oil solvent extraction plant photos

Soybean oil solvent extraction plant photos

Craft features of soybean oil solvent extraction machine:

1. Adopting negative pressure evaporation can ensure excellent oil quality;

2. Extraction system is highly adaptable, and can adapt to different raw material ;

3. All equipments are provided with exhaust gas absorption systems with excellent absorption effect;

4. Full energy-saving design utilizes heat energy for many times and saves steam consumption;

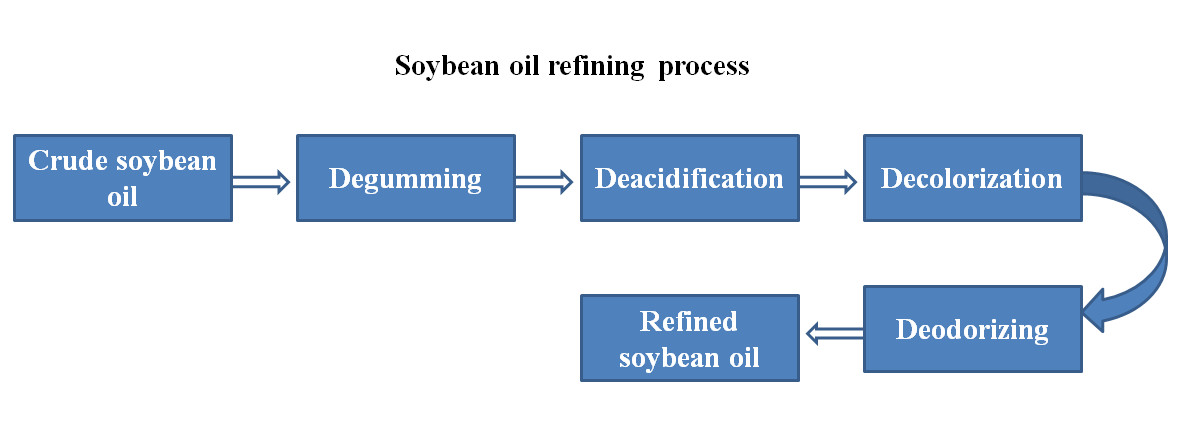

3.Crude oil refinery machine of Soybean Oil Mill Plant:

Soybean oil refinery plant is the final workshop in soybean oil mill plant. Soybean oil refinery plant is used to remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in crude soybean oil. The soybean oil refinery process includes the following process: degumming process, deacidification process, decolorization process, and deodorization process. Please read on, you will know the soybean oil refinery process.

Soybean oil refinery process flow chart:

Crude soybean oil → degumming and deacidification→ decolorization →deodorization → refined soybean oil.

Soybean oil refining process flow chart

Soybean oil refining process flow chart

Main process of the crude soybean oil refining:

1. Crude soybean oil degumming process,

2. Crude soybean oil deacidification/neutralization process

3. Crude soybean oil decoloring process

4. Crude soybean oil deodorization/distillation(deodorising unit) process

Small scale soybean oil refinery plant photos

Small scale soybean oil refinery plant photos

There are different capacities available for the Soybean Oil Mill Plant. We can provide and supply small scale as well as large scale soybean oil plants. The common capacity is of 3-TPD, 6-TPD, 10-TPD, 15-TPD, 20-TPD, 30-TPD,50-TPD,60-TPD and so on.

Henan Doing Company has already undertaken and installed many edible oil mill projects. Doing Group have rich experiences in setting up soybean oil mill, anyone who need to buy soybean oil mill plant can contact us!