The solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean after flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

Main equipment in vegetable oil solvent extraction plant

Main equipment in vegetable oil solvent extraction plant

In order to meet different clients’ requirement on different solvent extraction plants, we established a large scope of vegetable oil solvent extraction equipments with capacity from 20tpd to 1000tpd. For some special requirements, our engineers can design vegetable oil solvent extraction process for them .

Related parameter of vegetable oil solvent extraction plant:

| Product name: | Vegetable oil solvent extraction plant |

| Production capacity: | 30-1000tpd (can be customized) |

| Main process: | oil extraction/leaching, wet meal dissolving and drying, miscella oil evaporation and stripping, solvent steam condensation and recovery. |

| Main equipment : | Rotocel extractor, DTDC toaster, Miscella tank, 1st evaporator, 2nd evaporator, stripping tower , condenser |

| Application: | Low oil content oilseeds: soybean oil, rice bran oil; High oil content oilseeds: Peanut, sunflower,cottonseeds, rapeseed, mustard... |

What is the principle of vegetable oil solvent extraction plant?

Solvent extraction method is utilizing the solvent which can dissolve the oil fat, through wetting, permeating and molecular diffusing principle to extract the oil out from the oil seeds, then separating the crude oil from the miscella of oil and solvent. Vegetable oil solvent extraction plant can extract the oil out maximum. After vegetable oil solvent extraction plant, the oil residual rate in cake is less than 1%.

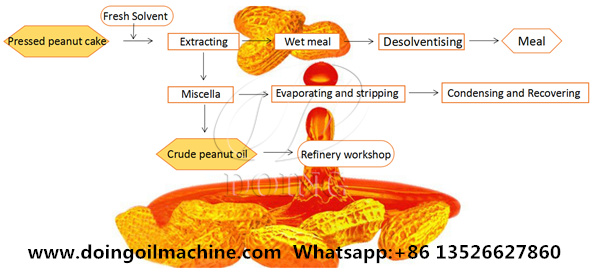

Vegetable oil solvent extraction process flow chart:

Vegetable oil solvent extraction process flow chart

Vegetable oil solvent extraction process flow chart

Vegetable oil solvent extraction process introduction:

The vegetable oil solvent extraction process mainly includes four parts:

oil extraction/leaching, wet meal dissolving and drying, miscella oil evaporation and stripping, solvent steam condensation and recovery.

Operation proces of vegetable oil solvent extraction plant:

Oil extraction/leaching : After pretreatment of oilseeds, the raw material embryo or prepressed cake is sent to the cooking oil extractor by the conveying equipment. After vegetable oil extraction proces,s we can get wet meal and miscella oil .

Wet meal dissolving drying: the meal discharged from the oil extractor contains 25% ~ 35% of the solvent, in order to make these solvents can be recovered and obtain better quality of the meal, wet meal drying is necessary.During Wet meal dissolving drying process, the DTDC desolventizer toaster will be used to obtain high quality meal..

Miscella oil evaporation and stripping: After oil extractor, mixed oil contains solvent , which need evaporate . Evapotation is using different boiling point between oil and solvent to make solvent transform into gas evaporated.

Solvent condensing and recoving: Use condenser to make the cake cool and recovery solvent.

Vegetable oil solvent extraction plant

Vegetable oil solvent extraction plant

Technical parameters of vegetable oil solvent extraction plant:

| Capacity | 30-500T/D |

| Residual oil in meal | ≤ 1% |

| Solvent consumption | ≤ 2Kg/T (No.6 solvent oil) |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Steam consumption | ≤ 280KG/T (0.8MPa) |

| Finished meal moisture | ≤ 13% (adjustable) |

| Residual solvent in finished meal | ≤300PPM (qualified detonated experiment) |

To meet every client's requirements, we offer a wide range of vegetable oil solvent extraction plant of different capacities. If you choose Henan Doing Company, we will customized a reasonable vegetable oil solvent extraction process solution for you.