In order to get high quality corn oil,the corn oil production process machinery is necessary.There are thress main process in corn oil production process machinery.They are corn oil press process,corn oil extraction process and corn oil refining process.

Corn (maize) is one of the main grain crops in the world. It is native to central and South America. Now it is mainly distributed in latitude between 30 to 50°, such as the United States, China, Brazil, Mexico, South Africa, India and Romania.

Now many countries use corn to make edible oil. One reason is that: according to research, the total fat content of corn grain is 3.1-5.7%, and 80-85% of the oil was enriched in corn germ. Therefore, the corn oil production mainly adopts germ extraction (separation) production technology. The other reason is that: the cost of setting up a corn oil production factory is not that high, if you buy corn oil production machines from Chinese manufacturers.

Corn germ and corn oil

Corn oil production process technology:

The corn oil production process generally includes 2 processes: germ separation and maize germ oil pressing.

Corn germ separation section:

The first step of corn oil production process is the separation of corn germ. There are 3 kinds of corn germ separation methods: dry method, wet method and half-wet (semi-wet) method.

Dry method corn germ separation section:

That is, the corn does not carry on the water regulation procedure, but is directly processed by mechanical method of extrusion or impact to separate skin, the embryo and the endosperm. This technology is simple, energy consumption is low, and no pollution; but the efficiency of the extraction is low, and the embryo contains more endosperm.

Wet method corn germ separation

This is a method that includes corn soaking, crushing, degerming, and separating germ from starch by rotary liquid separator. The germ separation efficiency can reach 85%~95%. As the water content of germ is as high as 60%, it must be dried. After drying process, its water content is 2%-4%, and oil content is as high as 44% ~50%. Therefore this wet method corn germ separation consumes higher energy and pollutant to environment. besides, its equipment investment and production cost are high, while the investment recovery period is long.

Half-wet corn germ separation

The principle of this method uses the nature that of corn germ and endosperm have different water content and water-absorbing quality, and after water absorbing, they have diversity in elasticity, toughness and crushing strength, to choose suitable equipments for corn breaking, peeling and degerming. Then uses different physical characteristics of embryo and endosperm to press the germ flat, and crush the endosperm; after sifting, sort out germ, in order to achieve the purpose of germ extraction. This method tempers the corn till the water content reaches 16% to 20%, and then peel, crush and grind the corn to get corn germ. This embryo extracting efficiency can reach more than 85%, with low energy consumption, no pollution, less equipment investment, short payback period of investment and low production cost; but the embryo contains a certain amount of endosperm.

Corn oil production process introduction:

There are 2 ways to make corn oil from corn germ: one is pressing method corn oil production, which is suitable for small to medium size oil mill plant; the second is solvent extraction method corn oil production, which is suitable for large scale oil factory; the third is aqueous enzymatic method corn oil production, which is a new method developed in recent years. At present, most of the oil factories in China adopt pressing method to make corn germ oil; but the output rate of oil is only 65% produced by this technology. There are only a few large enterprises that produce corn germ oil by adopting both pressing method and solvent extraction method. This corn oil processing technology combination can realize oil yield 97%.

Pre-pressing process of corn oil production process:

Generally use screw oil press in palm oil production process. To ensure higher oil yield, in addition to meet the above conditions, the pressure of corn oil press shall be above 69 MPa. After pressing, residual oil in the cake is controlled at 6% to 7%, and the moisture content of the cake is 3% ~ 4%. For safety reasons, the moisture content of the cake shall be adjusted to 12%.

Pressing way of corn oil production process

Solvent extraction of corn oil production process:

The moisture content of the corn germ must be controlled in a proper range to meet later pre-pressing and solvent extraction corn oil production process moisture requirements. At the same time, proper moisture content is also conducive to the corn germ flakes do not stick to the rolling stock, easy to make maize embryos pressed into uniform slices, and create favorable conditions to reduce residual oil in flakes. The suitable water content of the dried flakes is 10% ~ 11%. To prevent the powder of the flakes, the thickness should be controlled at 0.35 ~ 0.45mm. Steaming, pre-pressing and cooling can further change the internal and external structure of the germ particles, so that the protein can be frozen and modified to reduce the resistance of the oil molecules spread outward, at the same time adjust the moisture and temperature of the material. For the corn germ in pre-pressing &solvent extraction technology, the water requirement of the material shall be controlled at 4% ~ 6%. For 6# solvent oil, the temperature of the feeding corn germ flakes is better controlled at 50 ~ 55℃. The operation of the corn germ solvent extraction, purification, evaporation and solvent recovery is conducted as normal solvent extraction process.

Solvent extraction way of corn oil production process

Aqueous enzymatic corn oil production:

The aqueous enzymatic solvent extraction technology is a process that extracts oil from plants with a mixed liquid of water and enzyme. It’s a new type corn oil production technology.

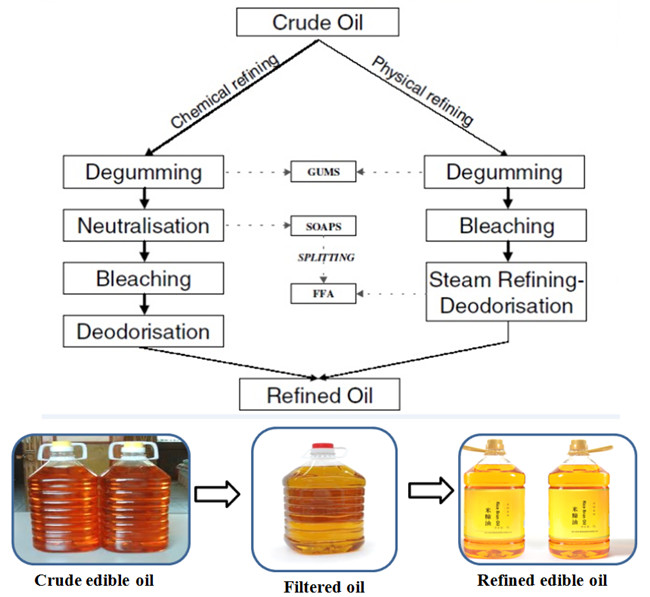

Refining of corn oil production process:

Refining of corn oil production process

Crude corn oil has deep amber color. It contains 1-3% phospholipids, >1% sterols, tocopherols or other unsaponifiables, 1.5% free fatty acid, 0.05% wax and unpleasant smell. Crude corn oil has high impurity content and gets turbid when temperature is low, so it cannot be used directly. After refining treatment can get low cloud point, low melting point and good storage stability refined corn oil or salad oil. After further processing of corn oil production machine, corn oil can also be used as a humanized milk power, child and elderly health food, medicine and senior cosmetics raw material oil.

Our company, Henan Doing Company devotes to provide solutions for corn oil production and corn oil refining, including corn oil production layout design, corn oil production machine manufacturing, corn oil production machine debugging and installation. At Henan Doing Company, you can find the BEST corn oil production process machinery.