| Featured Advantages of dry palm kernel oil fractionation: | Factors affecting dry palm kernel oil fractionation: |

|

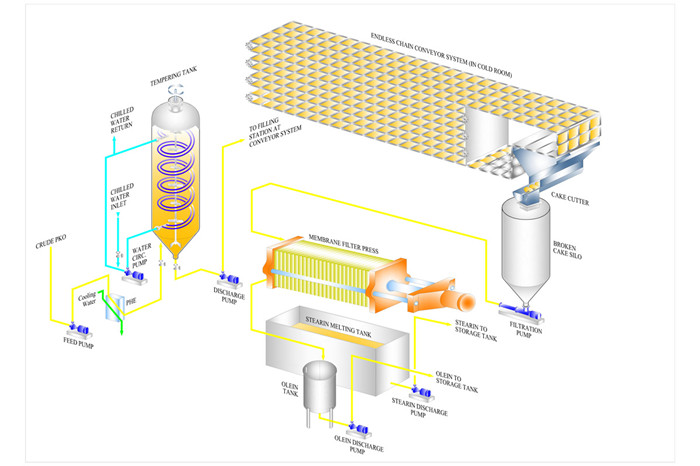

◆Simple oil fractionation process ◆Easy and convenient operation ◆Low consumption of steam ◆No environmental pollution ◆Satisfied palm oil fractionation results |

◆ Design of crystallizers ◆ Filter cloth air permeability (400, 600 L/dm2/min) ◆ Filling and Squeezing pressure ◆ Poor Control of Cooling Water Temperature |