Rice bran oil solvent extraction machines adopts the most advanced rice bran oil solvent extraction process to extract crude rice bran oil out. Compare with rice bran oil pressing process, the biggest advantage is that the residual oil rate is less than 1%.

Because of the low oil content of rice bran, about 16-20%, consideration of economic benefits, many large scale rice bran oil production factory choose rice bran oil solvent extraction process to extract rice bran oil.

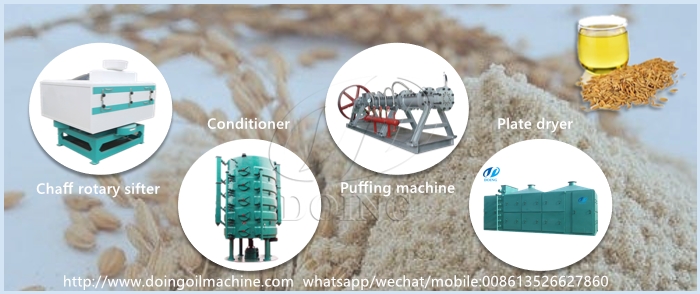

A rice bran oil solvent extraction plant not only need rice bran oil solvent extraction machines, but also require rice bran pretreatment machines, such as chaff rotary sifter, conditioner, puffing machine and plate dryer. Like the following picture shows:

Four rice bran pretreatment machines used in rice bran oil solvent extraction plant

Four rice bran pretreatment machines used in rice bran oil solvent extraction plant

These machines can process the rice bran to the best condition for being sent to the rice bran oil solvent extraction machines.

Rice bran oil solvent extraction machines can be divided into four systems: Solvent extraction system, D.T.D.C system, Mixed oil stripping and steaming system, Solvent recycling system.

Rice bran oil solvent extraction plant overall show

Rice bran oil solvent extraction plant overall show

1) Solvent extraction system in rice bran oil solvent extraction plant

This system uses solvent (n-hexane) to extract oil from the pretreated rice bran. After this step, two kinds of products will be got. One is wet meal with solvent, and the other one is mixed oil (solvent and rice bran oil).

Three types of oil extractor you can choose

Three types of oil extractor you can choose

The rice bran oil solvent extraction machine used in this step is oil extractor, which has three types: rotocel extractor, loop-type extractor and ballyuan extractor. Which one will be chosen is depending on the input capacity of your rice bran oil solvent extraction plant. And the engineer of Henan Doing Company will give you the professional suggestions.

2) D.T.D.C system in rice bran oil solvent extraction plant

D.T.D.C system used to desolventize from the wet meal

D.T.D.C system used to desolventize from the wet meal

D.T.D.C system is used to process the wet meal from oil extractor. Through four steps: desolventize -- toast -- dry -- cool to separate the rice bran meal and the solvent. The rice bran meal can be sold as animal feed.

The rice bran oil solvent extraction machine used in this step is a tower named D.T.D.C tower (evapo-separated machine).

3) Mixed oil stripping and steaming system in rice bran oil solvent extraction plant

Mixed oil stripping and steaming system

Mixed oil stripping and steaming system

The main rice bran oil solvent extraction machines in this section are 1st evaporator, 2nd evaporator and stripping tower. After these three machines processing, the solvent will be separated from the rice bran oil completely. In the process, the temperature of 1st and 2nd evaporator is about 95℃ and 110℃ and the temperature of the stripping tower is about 130℃.

4) Solvent recycling system in rice bran oil solvent extraction plant

The solvent from the D.T.D.C system and mixed oil stripping and steaming system will be cooled and recycled by the condensers. Then the solvent can be used again.

All the rice bran oil solvent extraction machines are controlled by PLC, cooperated with vacuum evaporation oil extraction design, solvent condensation and tail gas recovery system. The whole rice bran oil solvent extraction plant is high oil yield, low residual oil, low solvent consumption and low equipment failure. To get free quotation, please write down your requirement.