Palm oil

Palm oil is a kind of plant oil made from palm fruit. It is one of the largest produced, consumed and traded oils in the world, which is called The World’s Three Major Vegetable Oils together with soybean oil and rapeseed oil. Palm oil after pressing, refining and fractionation can get different melting point products, which are widely used in catering industry, food industry and oil & fat industry. As the main production areas of palm oil, Southeast Asia and Africa produces about 88% of the world's palm oil, while Indonesia, Malaysia and Nigeria are the world's top three palm oil producers. Since global demand is on the rise, so set up the palm oil mill plant is necessary. But there are many requirements for setting up a palm oil mill plant in nigeria which demands a feasibility study. These requirements include palm oil production machine, available market, money , and labor. The project of setting up the palm oil mill plant should be technically, financially and environmentally feasible.

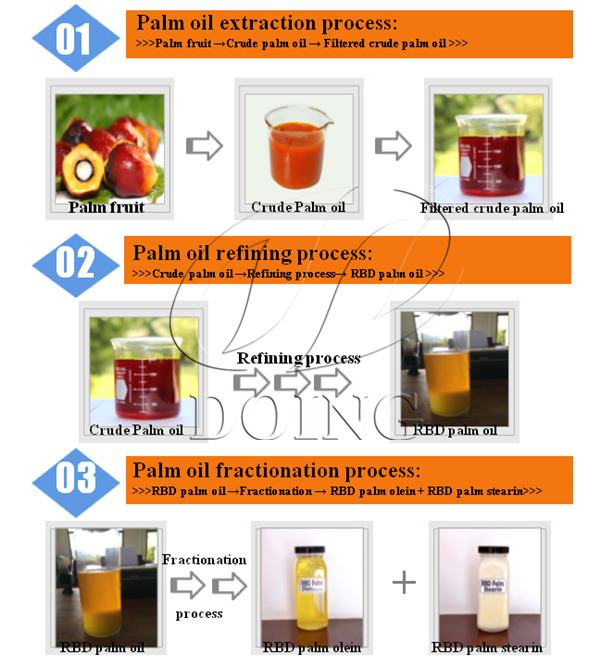

Palm oil production process

Opportunity

First, you need to identify if there is a business opportunity in a given area, country or region. A growing demand for palm oil provides an economic opportunity. The abundance of palm trees guarantees a continuous supply of palm fruits. Palm oil processing is labor intensive. The youthful workforce provides cheap labor depending on area of operation. There should also be an opportunity to manufacture further refined products.

Technical Feasibility

Advanced methods of production require new palm oil processing equipment which can be expensive. You need palm fruit reception machine, palm fruit sterilizing machine, palm fruit threshing machine, palm fruit digesting & pressing machine, crude palm oil clarification machine and others. High costs can discourage intending processors from investing and setting up new palm oil mill plants. You can choose to set up small scale palm oil mill plant, medium-sized palm oil mill plant or large scale palm oil mill plant and so on.

Financial Feasibility

Setting up the palm oil processing plant and purchasing equipment requires funds. It also takes into consideration wages and salaries to be paid to employees. Available funds determine the size of the plant and amount of palm oil produced. Economic stability and profitability of palm processing need to be analyzed. There should be demand for palm oil to guarantee profits in the long run. A feasibility study will help determine if the business plan has enough resources to fund the project. Financial implications of oil processing form the basis of the processing business. Palm oil economics uses profitability models like Benefit-Cost Ratio to determine the cost of palm fruits, transportation, hiring/purchasing equipment, availability of labor and market price.

Environmental Feasibility

An environmental impact assessment needs to be carried out as provided by the law. It helps to determine any negative impacts when establishing and operating the plant. Fortunately, all by-products from a palm oil processing plant are recyclable. Empty palm fruit bunches, palm shells can be used as fuel of boiler.

In conclusion, a financially, technically and environmentally feasible project benefits all whenever an opportunity presents itself. The owner of the palm oil processing plant will earn profits. Local people will get jobs, palm oil, and refined products. The products are also recyclable. Carrying out a feasibility study and following laws of the land determines the success of a palm oil processing enterprise.

The production of palm oil can be divided into 2 processes: palm oil pressing process and palm oil refining process.

Palm oil pressing technology

And for the palm oil pressing machine, we can do different capacites:

Small capacity: 1tph, 2tph, 3tph, 5tph.

Large capacity: 10t/h,15t/h, 30t/h 60t/h, to 120tph.

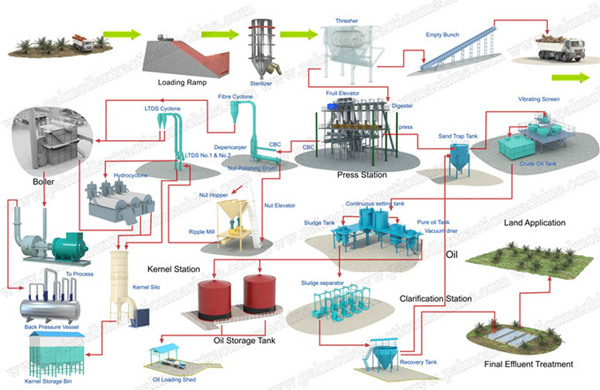

Process flow chart of palm oil pressing process:

Palm oil pressing process

Main processes of palm oil pressing machine:

Palm fruit sterilization station: Palm fruit sterilization station utilizes high temperature (145℃, 90-120min) to cook palm bunches. Palm fruit sterilizing machine can ensure palm fruit become soft and easy separate.

Palm fruit sterilizing machine

Palm fruit threshing station: Palm fruit threshing station can vibrate palm fruit from palm bunches efficiently. It makes further preparation for next step palm oil production process.

Palm fruit sterilizing machine

Palm oil digesting & pressing station: Palm fruit digesting machine is used for heating and cooking the palm fruit, to make it suitable for pressing, doing like this can help final user get the maximum oil and good quality cakes. Palm oil pressing machine can efficient extraction of palm oil. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

Palm fruit digesting and pressing machine

Crude palm oil clarification station: After crude palm oil clarifying machine, the obtained crude palm oil purity can reach up 90%. Crude palm oil clarification machine is the necessary machine in palm oil making machine.

Crude palm oil clarification machine

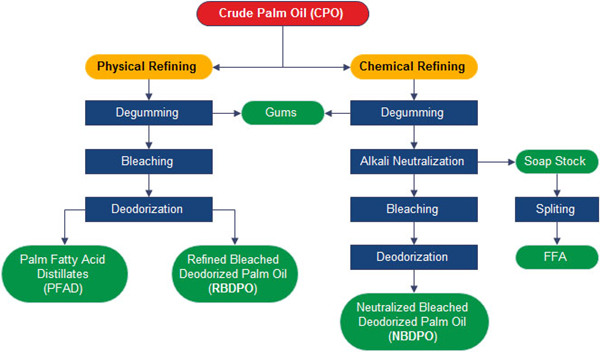

Palm oil refining technology

After palm oil pressing process, we can get crude palm oil. Crude palm oil shall be refined in complete palm oil refining line to get rid of FFA, natural pigment (decolorization) and odor (deodorization), and become salad lever oil – refined palm olein (RBD PO) and palm salad oil (RBD PKO).

Process flow chart of palm oil refining process:

Palm oil refining process

Main processes of palm oil refining machine:

Deacidification/ Neutralization: Use NaOH to react with FFA inside oil. Then the reaction product soap stock will be discharged.

De-gumming: Use hot water to mix with crude oil to remove the gum inside oil. Then dry the oil for bleaching process.

Decolorization /Bleaching: Use the bleaching earth to take the impurities out. Then use the filter to remove the bleaching earth.

Deodorization: Deodorization process is used to remove unacceptable odour by Steam Distillation.

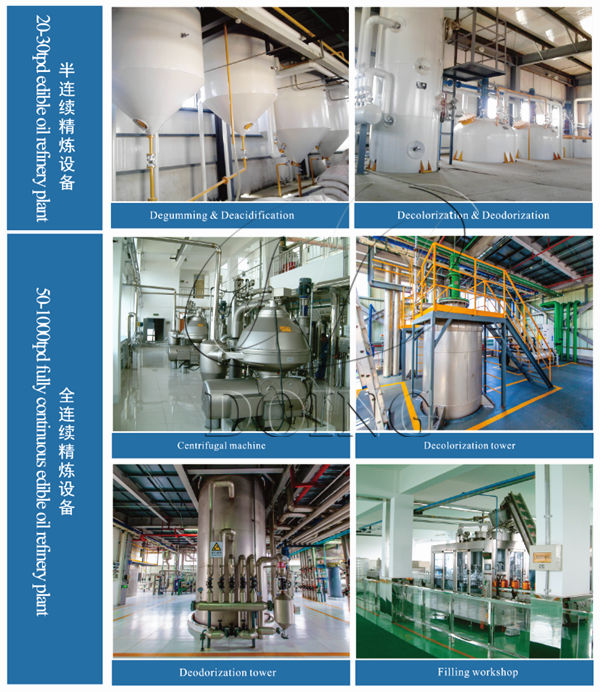

Semi-continuous palm oil refining machine and fully continuous palm oil refining machine

Henan Doing Company is now the largest palm oil processing plant manufacturer and supplier in China. We can not only supply high quality single palm oil expeller, but also offer turnkey projects of palm oil production machine, including palm oil extraction machine, palm oil refinery plant and palm oil fractionation plant. Our palm oil machine business scope as follows:

1-10tph small scale palm fruit processing plant;

15-45tph medium scale palm fruit processing plant;

60-120tph large scale palm fruit processing plant;

1-1000tpd palm kernel oil processing plant;

1-600tph palm oil and palm kernel oil refinery & fractionation plant;

If you want a FREE quotation, feel free to leave your message below!