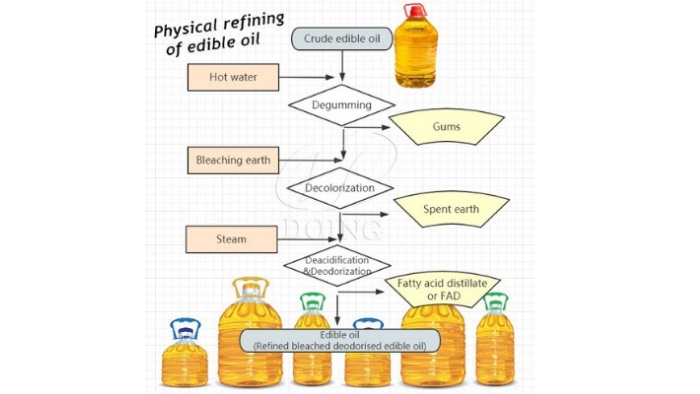

The crude rapeseed oil usually refined through four steps (include degumming, deacidification, decolorization, deodorization) to improve it’s quality and market value and extend the storage time, the following introduce these processes in detail for you:

Cooking oil refining machine

Cooking oil refining machine

1. Hydrationde gumming

In this step, we add hot water to dissolve colloidal impurities in crude rapeseed oil to remove excess phospholipids and make the color more vivid and obtain purer rapeseed oil;

2.Alkalizationde acidification

Due to the crude oil after degumming still contains excessive free fatty acids, so we need to add alkali to deacidify, let out the soap stock after settling and obtain acid-base neutralized refined rapeseed oil;

3. Clay adsorption decolorization

Then, we add white clay as an adsorbent to remove pigment in the crude oil and filter with a leaf filter after full reaction to improve the color of the oil and to obtain refined bleached rapeseed oil.

4.High temperature deodorization

Finally, the odor and part of free fatty acid in crude rapeseed oil were removed by distillation to improve the quality of the rapeseed oil further and obtain edible rapeseed oil.

Cooking oil refinery process flow

Cooking oil refinery process flow

Doing company is professional in rapeseed oil mill plant design and can provide you with the most professional rapeseed oil processing equipment and auxiliary equipment for you. If you are interested in establishing a rapeseed oil refinery plant or purchasing rapeseed oil refining machines, please contact us.