Pre-pressing & solvent extraction process is an important process to extract oil from oil seeds, which can extract oil more effectively and completely. And it’s especially suitable for the high oil content oil seeds, like peanut, sesame, sunflower seed, rapeseed, corn germ, etc.

Pre-pressing & solvent extraction process has been favored by many edible oil processing plants by virtue of its high oil yield features. And the detailed pre-pressing & solvent extraction processing process are as follows:

Pre-pressing is the basic part of pre-pressing & solvent extraction process. In this section, oil seeds with high oil content are adjusted to the best state by cleaning, shelling, crushing, drying, softening, flaking, cooking, and then pressed. During the pre-pressing section, most of the oil in high oil content oil seeds can be extracted, and the residual oil rate in the cake is about 7%.

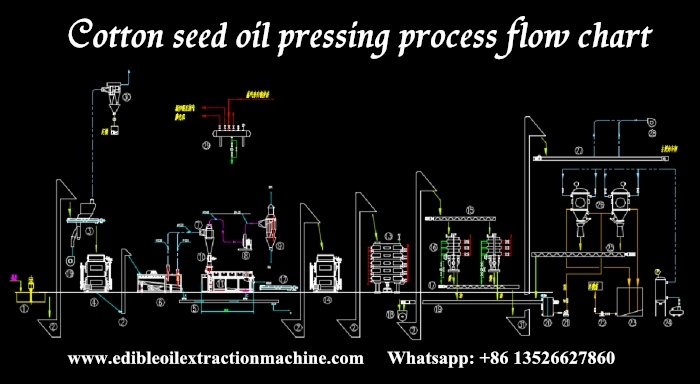

Cooking oil pre-pressing process flow chart

Cooking oil pre-pressing process flow chart

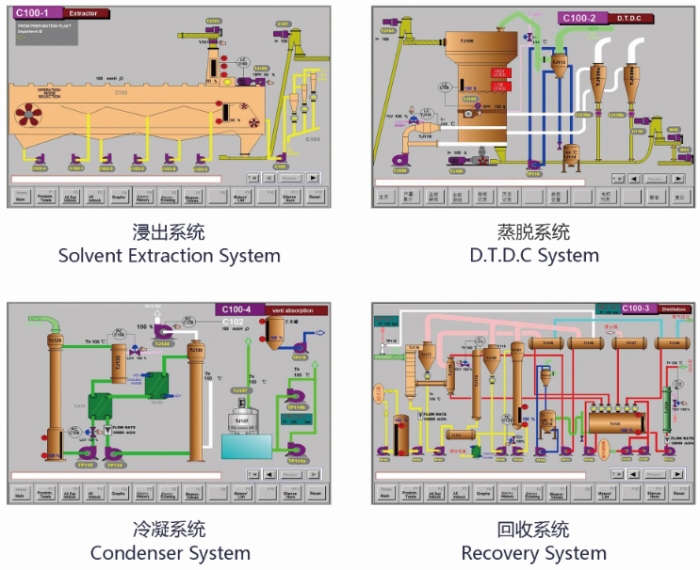

After pre-pressing, the processed oil seeds or pressed oil cake will enter the solvent extraction section for further extraction, and the detailed process are solvent extraction system—D.T.D.C system—condenser system—recovery system. In solvent extraction section, more crude oil will be extracted by taking advantage of principle that oil fat and the organic solvents can dissolve with each other. Generally speaking, the residual oil rate in the cake is below 1% after solvent extraction.

Cooking oil solvent extraction process flow chart

Cooking oil solvent extraction process flow chart

Henan Glory Company is a professional cooking oil processing machine manufacturer and directly supplier. Our engineering team & technical team can customize different scales cooking oil processing machine and processing solutions according to your oil seeds processing requirements and investment budget. If you have any investing ideas, let us help your cooking oil processing plant achieve more economic benefits!