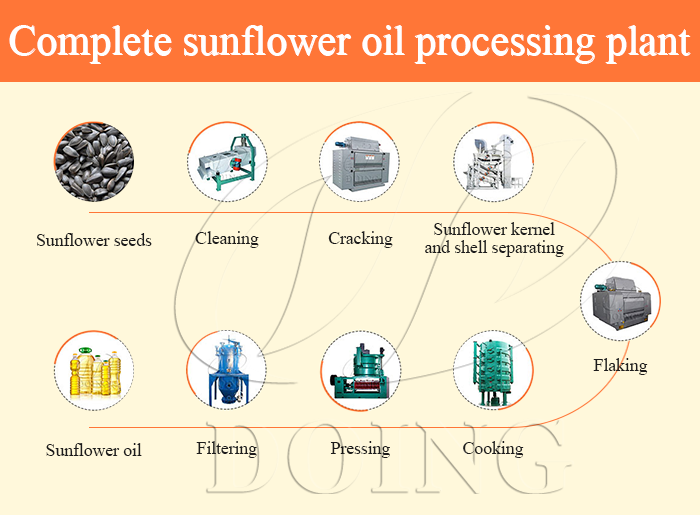

Sunflower seed oil is a nutritious, easily digestible and cholesterol-free vegetable oil that is becoming increasingly popular. However, to produce high-quality sunflower seed oil, a certain making process needs to be followed. Below, I will introduce the steps involved in the process of sunflower oil making.

Selection of raw materials

The quality of sunflower seed oil is influenced by the raw materials used. Therefore, fresh, mold-free, odorless and evenly colored sunflower seeds should be selected to ensure the oil yield and quality of the oil. Generally, the oil yield of sunflower seed oil ranges from 30-50%.

Cleaning

After selecting the raw materials, the sunflower seeds need to be cleaned to remove impurities such as soil, stones, and iron. These impurities can reduce the oil yield and quality and cause damage to the equipment. The cleaning process typically involves using vibration screens, magnetic separators, and destoners, achieving a removal rate of up to 99%.

Cleaning machine photo

Cleaning machine photo

Cracking

Sunflower seeds need to be cracked before pressing. At this stage, a sheller is needed to remove the hull. The presence of hulls can absorb oil and affect the oil yield. For production lines with a daily output of over 100 tons, it is recommended to use a crushing machine directly. Separating the kernel and shell can increase the oil yield.

Kernel shell separation

After cracking, the sunflower seeds and shells need to be separated. It is best to use wind power for separation, which ensures a high dehulling rate without affecting the sunflower seeds.

Flaking

As sunflower seeds are small, we use a flaking machine to flatten them and increase the pressing area and oil yield. The flaking machine must have enough pressure and an appropriate pressing head to ensure uniform flakes are produced.

Vegetable oil making machine photo

Vegetable oil making machine photo

Steaming and roasting

The hulled sunflower seeds are conveyed to a steamer-roaster to adjust the temperature and humidity of the oil. The optimal pressing temperature for sunflower seeds is about 100°C, with a water content of around 12%. In the steaming and roasting process, it is necessary to control the temperature, time, and humidity to increase the oil yield and quality.

Pressing

The steamed and roasted sunflower seeds are transported to an oil press for pressing. Generally, screw presses are used for sunflower seed oil production. Different brands of oil presses have different oil yields, typically ranging from 84-94%. Our company's sunflower seed pressing machine adopts a specialized design, achieving an oil yield as high as 94%.

Filtration and storage

After pressing, the sunflower seed oil may contain small amounts of residue. Therefore, the oil needs to be filtered using a filter. The filtered crude oil can then be transported to a storage tank for storage.

Sunflower oil making plant photo

Sunflower oil making plant photo

Of course, different sunflower seed processing volumes require different equipment. If you would like to learn more about the process of sunflower oil making and sunflower oil making machines, please contact us.