There are two methods of soybean oil production, one is mechanical way, which is a traditional method that use screw press machine to squeeze oil out from seeds and kernels; the other way is chemical method that extract oil with solvents. Both two soybean oil production methods have advantages and disadvantages. The previous one is natural and healthy but the oil yield is much lower, however, oil yield of the solvent extraction method is much more higher. You can choose one according to the capacity and your oil making needs, or you can use the two together.

Complete set soybean oil production machine

Screw soybean oil press machine is suitable for processing 5-20MT small capacity soybean. The residue of oil press is about 5%-7%. After processing by oil press, the final user can get crude soybean oil and soybean cakes. The soybean cakes can be used for making animal feed.

Small scale soybean oil press machine

Soybean Oil Production Process Flowchart:

Small scale soybean oil production line

Soybean oil solvent extraction plant is adopted to process large capacity soybean, the residue is less than 1%, at the meanwhile, the users can get high protein soybean meal which can be used for making animal feed. This is why more and more people are interested in soybean oil solvent extraction plant.

Soybean oil solvent extraction plant

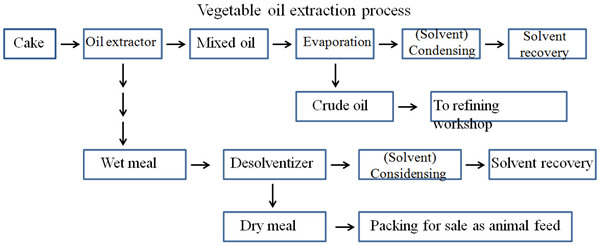

Soybean oil solvent extraction process Flowchart:

Soybean oil solvent extraction process

We are professional manufacturer of soybean oil making machine, besides soybean oil press machine, soybean oil solvent extarction plant, we also supply soybean oil mill plant, soybean oil extraction plant, soybean oil refining machine and so on.