Soybean oil and soybean oil mill machinery

Our company is specialized in manufacturing different edible oil mill machinery for different oilseed. In this article, I pay much attention to introduce soybean, soybean oil and soybean oil mill machinery.

Soybean oil introduction:

If you want to set up a soybean oil mill machinery, there is no doubt that the raw material is soybean.

Soybean is one of most important oilseeds all over the world. Soybean is distributed mainly over America(32%), Brazil(28%), Argentina(21%), China(7%),India(4%), Paraguay (3%), Canada(1%) and other countries.

Among the legumes, soybean is valued for its high (38–45%) protein content as well as its (approximately 20%) oil content. Soybeans can be broadly classified as "vegetable" or field (oil) types. Vegetable types cook more easily, have a mild, nutty flavor, better texture, are larger in size, higher in protein, and lower in oil than field types. Tofu and soy milk producers prefer the higher protein cultivars bred from vegetable soybeans originally brought to the United States in the late 1930s. Soybean can be made Chinese Tofu, soy milk, soybean oil, soybean meal, livestock feed, soy flour and so on in our daily life.

Soybean

Soybean

Approximately 85% of the world's soybean crop is processed into soybean meal and soybean oil, the remainder processed in other ways or eaten whole. The soybean oil content is about 18%. Soybean is a kind of low oil content oilseed compared with other oilseeds as, peanut, sesame, canoal,etc. So usually we adopts pretreatment and solvent extraction way to process soybean and get soybean oil. Compared with pressing way, pretreatment and solvent extraction way can reduce residue oil rate and increase oil productivity.

After solvent extraction, we can get soybean meal or soybean cake. It is better as animal feed than soybean cake after pressing.

Soybean oil

Soybean oil

How to make soybean oil from soybean seeds?

Soybean oil is a kind of vegetable oil that is extracted from the seeds of the soybean. Soybean oil is one of the most widely consumed cooking oils across the world. In order to process soybean oils from soybean, soybean oil mill machinery is necessary.

Our company is specialized in manufacturing cooking oil plant with different oilseeds. Different oilseeds have different processing technology. The following is soybean oil processing technology.

Soybean oil procduction process

About soybean oil mill machinery, the process from soybean to first-grade soybean oil has three workshops, they are pretreatment worshop, solvent extraction workshop and refinery workshop.

Soybean oil production process

Soybean pretreatment process:

Soybean---cleaning---stones removal---magnetic selection---crushing---softening---flaking---drying---to solvent extraction

Soybean pretreatment workshop is the basic process of soybean oil mill machinery, is mainly to remove impurities in soybean, regulate moisture and temperature of soybean, and break soybean into small particles to change soybean molecular structure,etc, which is good for the following process in solvent extracton workshop. After pretreatment, we can get soybean cake. Soybean cake can go to the following solvent extraction workshop. Soybean cake also can be used for extracting protein.

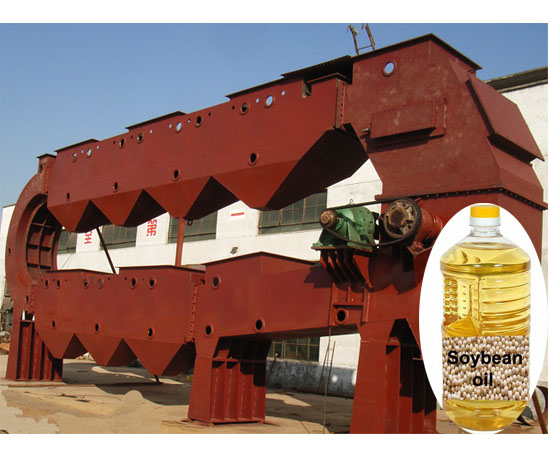

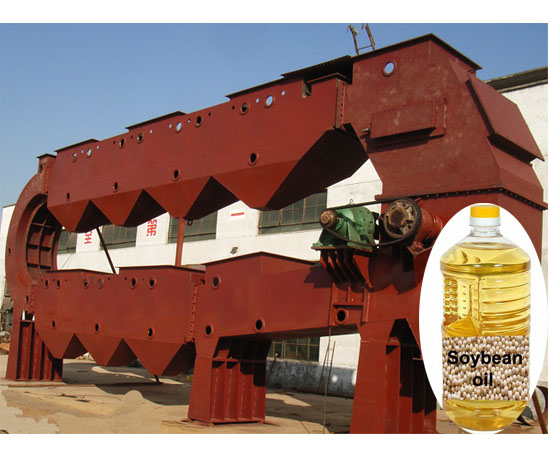

Single machines in soybean pretrearment workshop

Soybean solvent extraction process:

There are four big parts in solvent extraction workshop about soybean oil mill machinery.

They are solvent system, desolventizing system, condensing system and recycling system. We can get soybean wet meal and crude soybean oil.

Soybean wet meal can be as animal feed, crude soybean oil contains solid impurity, chemical impurity and smelly odour etc. So crude soybean oil can go to next refinery workshop.

Soybean solvent extraction machine

Quality indicators of crude soybean oil

|

Smell and flavour |

Smell and flavor , typical of soybean oil , without foreign smell |

|

Colour |

Natural, brown with green tinge |

|

Transparency |

slightly turbid, might have a small sediment |

|

Mass fraction of fatless substances,%, not more than |

0,20 |

|

Mass fraction of humidity, % |

0,36 |

|

Acid value, mg КОN/g |

4,00 |

|

Peroxide number, ½ mol/kg, not more than |

5,00 |

Mass fraction of substances which contain phosphates, %, not more than:

in calculation to stearooleolecitine |

4,00 |

|

Color quantity ( iodine value), not more than |

100 |

Soybean oil refinery process:

Crude soybean oil-degumming--deacidifaction--decolorization--deodorization--refined soybean oil.

After refining, we can get refined,bleached,deodorized oil. That is, first-grade soybean oil.

Soybean oil refinery machine

Quality indicators of refined soybean oil

Smell and flavour |

No smell; depersonalized oil taste |

|

Colour |

Light yellow |

|

Transparency |

Transparent |

|

Mass fraction of fatless substances,%, not more than |

none |

|

Mass fraction of humidity, % |

0,1 |

|

Acid value, mg КОN/g |

0,3 |

|

Peroxide number, ½ mol/kg, not more than |

5,00 |

Mass fraction of substances which contain phosphates, %, not more than:

in calculation to stearooleolecitine |

0,05 |

|

Color quantity ( iodine value), not more than |

12 |

Our company has manufacturing team, professional engineer team and sales team. we can advise you proper machine and also offer tunkey-project according to customers' requirements.

Doing Group is your best choice if you want to set up a perfect soybean oil mill machinery.