In solvent extraction plant, mechanical method is followed that comprises of high temperature, high pressure and high moisture. This helps in color fixation, oxidation and hydrolysis. There are some seeds like rice bran and soya that cannot be handled by the expellers.

Continuous solvent extraction plant is capable of handling all materials. It does not cause any kind of change of in the property of oil; instead, it recovers it with all the similar properties present in the raw material. We have solvent extraction plant in the capacity ranging from 50 TPD to 2000 TPD.

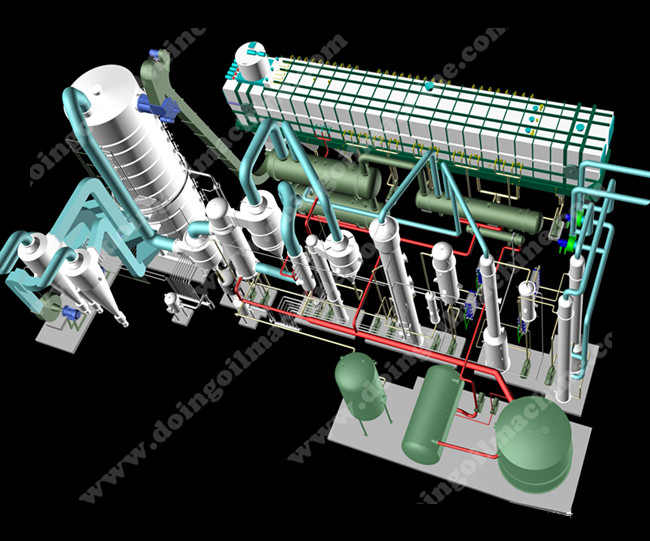

Cooking oil solvent extraction workshop

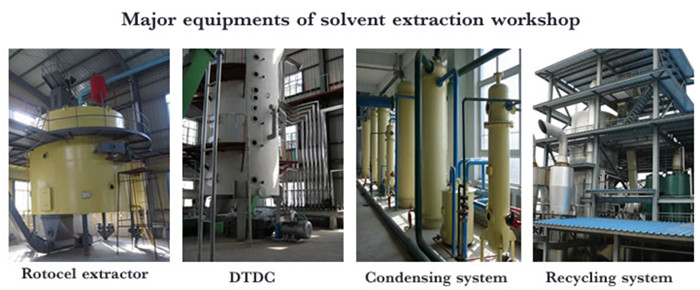

Our continuous solvent extraction plant consists of:

Seed preparatory section

Solvent extraction section

Distillation section

Meal de-solventising section

Recuperation section

Meal conditioning section

Solvent extraction plant

In the first process of preparation, seeds are properly prepared for extraction of oil either by solvent or mechanical method. A particular seed may contain from 20 % - 50 % oil which is bound within the cell. This oil content is taken out forcefully by mechanical action or by making the oil accessible to subsequent solvent extraction.

In the unit, operations that are carried out involve cleaning, scaling, cracking, conditioning (or cooking) and flaking. According to the type of oilseed and process, additional drying and hulling process may be employed.

The prime goal of carrying out this extraction process is to minimize the content of in oilseed to the possible level. The chain conveyor attached in the plant transfers the prepared material to the rotary airlock feeder, which further drops it to the feeding hopper in which the effective vapor seal regulates the feed. For the indication of high and low level, the hopper is provided with special flameproof level switches. The extractor is constructed from the best grade mild steel in rectangular design, installed horizontally. Pretreated material generated from the preparatory is moved on the specially designed articulated band conveyor present inside the extractor.

Depending on the demands of a process, the speed of the band conveyor can be adjusted for continuous travelling of the feed material under continuous solvent spray with determined speed and pre-calculated bed height. Adjustable damper is also there for adjusting the bed of feed material on band conveyor. High pressure jet spray of fresh solvent is used on to the return of band conveyor for its cleaning. The solvent is sprayed at discharge end for perfect cleaning of mesh with no possibilities of mash.

Choking & channeling

We have specially integrated well designed spray breakers for uniform distribution of solvent over the entire width of moving bed. For ensuring perfect counter current flow of the material and the solvent, the full miscella is recovered from the initial stage. Fresh solvent is also admitted into the extractor near the discharge end of the moving bed.

With the overflow from each hopper, the miscella circulates in a closed circuit in each of the successive section. This ensures, an equilibrium between the oil extracted from the seed in equivalent section and the difference in oil content of solvent overflowing the preceding hopper together with the solvent overflowing the following section.

Special features of solvent extraction plant:

Reduces the steam consumption.

Increases the capacity of distillation

Section increases the capacity of condensing section.

The miscella is pumped from the tank through the vapor economizer, to the first evaporator. The construction of the economizer unit well designed for effective utilization of heat of vapors emerging from the desolventizer toaster.

The miscella obtained from the economizer is concentrated and in the first evaporator, it is rapidly by means of low pressure steam. It then enters into the flasher, where solvent vapors are flashed off. The oil rich miscella thus obtained is charged into the second evaporator & stripper. Liquid solvent is re-circulated back to the process through solvent water separator along with condensation of flashed off solvent vapors into the condensers.

The factors responsible for good quality of oil are distillation system operating under high vacuum and lower temperatures and along with it short distillation period. Also, in addition to distillation system, final drying of oil in final oil heater is also done for production of oil with exceptionally low volatiles in it.