Rice bran oil and rice bran oil mill machinery

Rice bran oil introduction:

Rice bran oil is the oil extracted from the hard outer brown layer of rice after chaff (rice husk). It is notable for its high smoke point of 232 °C (450 °F) and its mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying. It is popular as a cooking oil in several Asian countries, including Bangladesh, Japan, India and China.

Rice bran oil

The specification of crude rice bran oil and refined rice bran oil

|

character |

Crude Rice bran oil |

Refined rice bran oil |

|

Moisture |

0.5-1.0% |

0.1-0.15% |

|

Density(15-15℃) |

0.913-0.920 |

0.913-0.920 |

|

Refractive Index |

1.4672 |

1.4672 |

|

Iodine value |

85-100 |

95-104 |

|

Saponification value |

187 |

187 |

|

Unsaponifiable matter |

4.5-5.5 |

1.8-2.5 |

|

Free fatty acids |

5-15% |

0.15-02% |

|

oryzanol |

2.0 |

1.5-1.8 |

|

Tocopherol |

0.15 |

0.05 |

|

Color(Tintometer) |

20Y+2.8R |

10Y+1.0R |

Rice bran oil processing machine

How to make rice bran oil?

Rice bran oil yield rate is 18%-20%. Compared with other oil seeds, rice bran oil content is low.The best way for rice bran oil is solvent extraction way.The complete rice bran oil processing process is rice bran cleaning machine,rice bran puffing machine,rice bran drying machine,rice bran ewxtraction machine,rice bran oil refining machine ,and rice bran dewaxing machine.

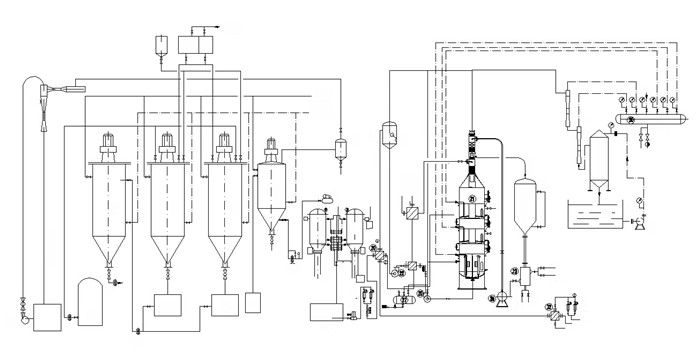

The rice bran pretreatment/press process as follows:

1) Magnetic:The first step is to move the iron in the peanut, because the iron will harmful to the following machines.

2) Cleaning: After going through the cleaning sieve, the impurities in the rice bran will be cleaned.

3) Bulking / Puffing /Extruding machine: This is the special machine for rice bran. This machine make the rice bran to pellet. The pellet is easy for absorbing solvent and get oil by the solvent extraction way.

4) Dryer: After making the pellet, the water content of rice bran need be changed to 7-9%. This water content is most suitable for solvent extraction section.

Rice bran oil extraction process:

After rice bran oil pre-pressing process, the rice bran will be send to oil extraction workshop.Rice bran will go through soaking or spraying contact methods to extract oil. After the solvent extraction process, there is only less 1% oil content in meal.

Craft flow for rice bran oil extraction workshop:

solvent steam

↓ ↓

extraction → mixed oil → evaporation → steam-stripping → crude oil

The rice bran oil extraction machine applies to rapeseed, soybean, cotton seed, camellia seed, sunflower seed, rice bran, corn germ, etc.

Rice bran oil extraction related parameters:

|

Capacity |

30-500T/D |

|

Residual oil in meal |

≤ 1% |

|

Solvent consumption |

≤ 2Kg/T (No.6 solvent oil) |

|

Crude oil moisture and volatile matter |

≤ 0.30% |

|

Power consumption |

≤ 15KWh/T |

|

Steam consumption |

≤ 280KG/T (0.8MPa) |

|

Finished meal moisture |

≤ 13% (adjustable) |

|

Residual solvent in finished meal |

≤300PPM (qualified detonated experiment) |

Rice bran oil refining process:

After oil pressing process or oil extraction process, we get crude rice bran oil. But the crude rice bran oil can’t flow to supermarket. The crude oil must need processing with cooking oil refining plant.So the rice bran oil refining machine is necessary.

Working principle of rice bran oil refining machine:

(1)Pump crude rice bran oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C -80C after one hour. Add acid or alkali to separate according to the acid value. After one hour's processing and 4-6 hours deposit, then convey soap stock to storage tank.

(2)Pump refined rice bran oil into decoloring tank. When it is up to 90-110°c after one hour's heating, add clay into tank for 20min's processing. Then separate clay and oil with filter.

(3Put discolored oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal.After filtering, you will get final oil product.

Cruderice bran oil refining effect:

• After refining the impurity of oil must be less than 0.2% ;

• Recycling system save power and money;

• Lower oil waste.