There are two main processing methods of cottonseed oil: one is the pretreatment pressing method, and the other is the solvent extraction method. Different processing methods use different cottonseed oil processing machine, so what are the processing machine of cottonseed oil? This article will give you the answer.

The first method: pretreatment pressing method

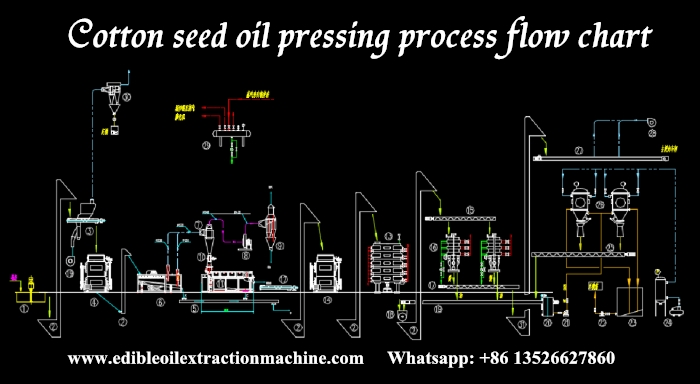

Cottonseed oil pressing process flow chart

Cottonseed oil pressing process flow chart

First, a special wind separator is used to remove light impurities and heavy impurities in the cottonseed, and the cleaned cottonseed needs to be shelled, and a disc sheller is used to achieve the desired effect. Then a kernel shell separator is needed to separate the shell from the kernel, so you get a clean kernel for the next step. The cleaned kernels need a roaster to make them soft and easy to press. The most important thing is the pressing procedure, choose the right oil press machine, so that the oil yield is high and more economical. Cottonseed oil is filtered through a filter press to remove impurities and obtain cleaner crude oil.

The second method: solvent extraction method

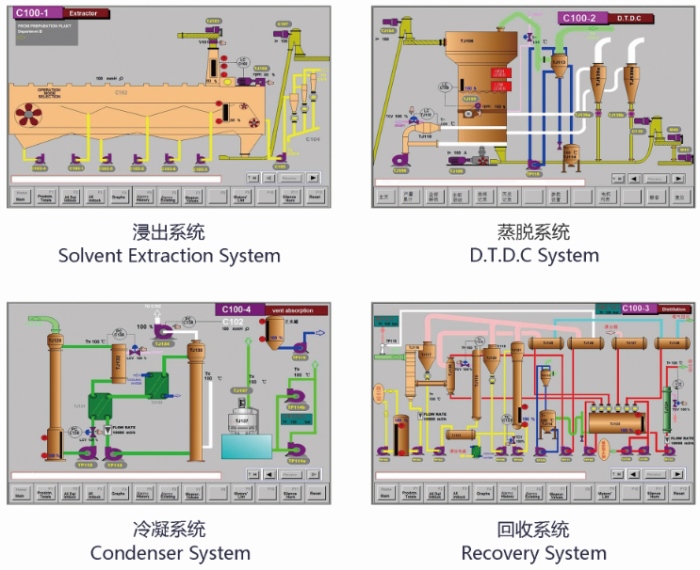

Solvent extraction process

Solvent extraction process

This method has a relatively low residual oil rate and is widely used in oil extraction. The pretreatment stage is the same as the pressing process. The first process of extraction is the solvent extraction section. The second process is miscella evaporation and stripping. The purpose is to remove the solid coarse powder and separation solvent in the oil, so as to obtain relatively pure extracted crude oil. The third step is to desolventize the baked meal. The wet powder coming out of the extractor usually contains 20%-40% solvent and must be recovered by dissolution and drying. The final step is solvent recovery.

If your processing capacity is small and the budget is limited, it is recommended that you choose the pretreatment pressing method. The required machines includes: cleaning machine, shelling machine, kernel shell separation machine, roaster, oil press, filter, etc.. The solvent extraction method is suitable for cottonseed oil extraction projects with a large amount of raw materials and high investment. In addition to pressing machine, we also need to use solvent extraction machine.(Recommend reading: Cottonseed oil pretreatment and pressing machine)

Cottonseed oil pretreatment and pre-pressing machine

Cottonseed oil pretreatment and pre-pressing machine

The above is a brief introduction of the cottonseed oil extraction method and cottonseed oil processing machine. If you have more questions about cottonseed oil extraction, please consult Henan Glory Company. We have professional engineers to answer your questions and provide you with high quality cottonseed oil processing machine.