Refining is an essential process for a complete vegetable oil production line because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude oil. Vegetable oil refining process is a complex process which includes degumming process, deacidification process, decolorization process, deodorization process.

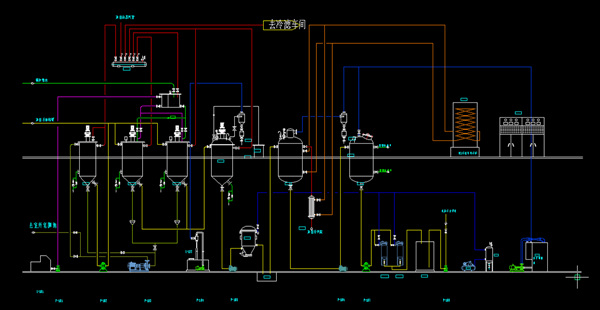

Vegetable oil refining process flow chart:

Batch type vegetable oil refining process flow chart

Batch type vegetable oil refining process flow chart

Vegetable oil refining process as follows:

(1)Pump crude edible oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour. Add acid or alkali to separate according to the acid value. After one hour's processing and 4-6hours deposit, then convey soap stock to storage tank.

(2)Pump refined oil into decoloring tank. When it is up to 90-110°C after one hour's heating, add clay into tank for 20min's processing. Then separate clay and oil with filter.

(3)Put decolorizing oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal. After filtering, you will get final oil product. Note: (1)We have the different oil mill factory for the visit.

(2)We supply for the turn-key project now and then.

(3)We are doing! Welcome to visit our factory!

Henan Doing has manufacture vegetable oil refinery plant for more than 40 years, and our soybean oil refining machine, palm oil refining machine, peanut oil refining machine has exported to many countries. We have professional engineers who will give you the best suggestions. If you want to know more information about vegetable oil refining process, please feel free to contact us!