Palm kernel is a kind of oil seeds got after extracting palm oil. The palm kernel has 45 % ~ 50 % of oil. The oil extracted from palm kernel is called Palm Kernel Oil (PKO) with extensive applications. Recent years, more and more businessmen saw the value of palm kernel oil, starting to set up palm kernel oil mill plant. This article will introduce the machines used in palm kernel oil extraction process. If you are interested in it, please continue reading.

1. Palm kernel cracking and separating machine

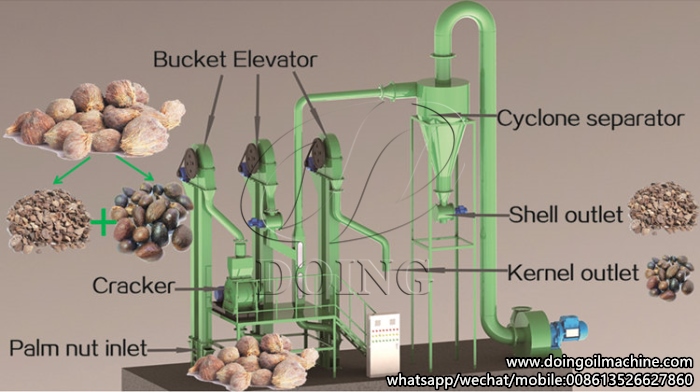

The 3D picture of palm kernel cracking and separating machine

The 3D picture of palm kernel cracking and separating machine

The palm kernel cracking and separating machine is used to husking and them make the shell and kernel separate. If your raw material is palm kernel with shell, the palm kernel cracking and separating machine can improve the efficiency a lot.

The working principle of the palm kernel cracking and separating machine:

a. use cracking machine to make the palm kernel be broken. The cracking rate is more than 90%, and it will not break the palm kernel.

b. use air separator system. Through adjusting the transducer to control high pressure air speed and volume, the kernel and shell will be separated. The separating rate is more than 95%.

Related project: The palm kernel cracking and separating machine was successfully installed in Nigeria

2. Small scale palm kernel oil pressing line

The 3D picture of small scale palm kernel oil pressing line

The 3D picture of small scale palm kernel oil pressing line

As the above picture shows, the small scale palm kernel oil pressing line contains drum frying pan, crashing machine, press machine and filter machine. This small scale palm kernel oil pressing line can be designed into 0.5-2 tons per hour input capacity, very popular among customers.

The functions of each machine in this small scale palm kernel oil pressing line:

a. Drum frying pan: adjust the temperature and moisture of palm kernel, to increase the oil yield.

b. Crashing machine: crash the palm kernel into small pieces, to make the press more easy.

c. Press machine: use physical extruding principle to get oil from palm kernel.

d. Filter machine: filter the crude palm kernel oil to remove some impurities.

3. Medium or large scale palm kernel oil processing line

Because the palm kernel is high oil content oil seed, when the input capacity is more than 30 tons per day, engineers will recommend you to use pretreatment+pre-press+solvent extraction method. If you want to produce refined palm kernel oil, the edible oil refinery machine is also needed.

The 3D pictures of three workshops in palm kernel oil production process

The 3D pictures of three workshops in palm kernel oil production process

The functions of several main parts in medium or large scale palm kernel oil processing line:

a. Palm kernel pretreatment part: it includes cleaning, crushing, softening, flaking, cooking. The main function of this part is to remove the impurities of palm kernel, adjust the conditions of palm kernel, so as to benefit the press part.

b. Palm kernel pre-pressing part: use pre-press machine to extract most oil in palm kernel. And then the palm kernel cake will be sent into palm kernel oil solvent extraction plant to be further processed.

c. Solvent extraction part: use n-hexane to extract oil from palm kernel cake, and make the oil residual less than 1%. The palm kernel meal got after this part is very suitable as animal feed.

d. Refining part: use physical or chemical refining method, through degumming, deacidification, decolorization and deodorization four steps to make the palm kernel qualified the national standard.

Related project: 60tpd palm kernel oil pressing & extraction plant project in Nigeria

Do you have the plan to set up a palm kernel oil mill plant? Henan Doing Company can provide you different capacity palm kernel oil extraction machine and design the suitable project proposal. Come on sending your needs in the following table!