Palm kernel cracking and separating machine is a essential equipment in the palm kernel oil processing industry, and common problems can affect its efficiency and output quality. Below are some typical common problems in palm kernel cracking and separating machine and corresponding solutions:

Problem:

Low cracking rate or incomplete separation of palm kernels from shells.

Causes:

(1) Improper adjustment of the gap between the beating rod (rotor) and the teeth of the inner wall of the palm kernel cracking and separating machine.

(2) High moisture content in the palm kernels, making them tough to crack.

Solutions:

(1) Adjust the gap between the beating rod (rotor) and the teeth of the inner wall of the cracking mechanism to match the size and hardness of the palm kernels.

(2) Pre-dry the palm kernels to reduce moisture content before cracking.

Palm kernel cracking machine

Palm kernel cracking machine

Problem:

High percentage of broken palm kernels during the cracking process.

Causes:

(1) Excessive pressure or tight gap in the cracking machine.

(2) High-speed operation leading to impact damage.

Solutions:

(1) Reduce the pressure or increase the gap in the cracking machine.

(2) Lower the operating speed to minimize impact forces.

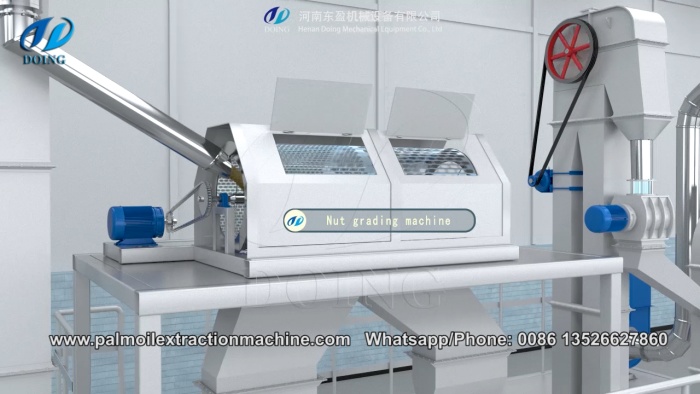

Based on the above two crushing problems, I recommend Henan Glory Company's palm kernel cracking and separating machine. It can be equipped with a palm kernel grading screen. You can choose to use it or not. The grading screen is used to grade the palm kernels into two batches according to the size of the palm kernels. The volumes of the kernels in the same batch are similar, so as to avoid the situation that the palm kernel diameter is too small to be shelled or the palm kernel diameter is too large to cause the kernels to be broken and incomplete.

Palm kernel grading screen

Palm kernel grading screen

Problem:

Poor separation of palm kernels from shells, leading to contamination and effect the quality of the palm kernel oil.

Cause:

Inadequate airflow or vibration in the palm kernel cracking and separating machine.

Solution:

Adjust the airflow or vibration intensity in the air separator system.

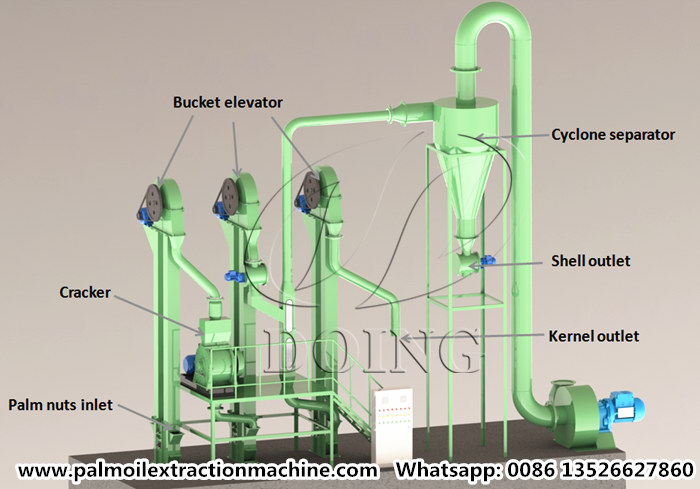

Air separator system

Air separator system

Problem:

Frequent jams or blockages in the feeding, cracking or separating sections.

Causes:

(1) Overfeeding or uneven feeding of palm kernels.

(2) Poor maintenance of palm kernel cracking and separating machine leading to accumulation of debris.

Solutions:

(1) Adjust palm kernel cracking and separating machine parameters to ensure that the feed rate is stable and controllable.

(2) Regularly clean and inspect the palm kernel cracking and separating machine to prevent debris buildup.

Palm kernel cracking and separating machine

Palm kernel cracking and separating machine

Problem:

High noise levels or abnormal vibrations during palm kernel cracking and separating machine operation.

Causes:

(1) Loose or worn-out palm kernel cracking and separating machine components (e.g., bearings, belts).

(2) Misalignment of rotating parts.

(3) Unbalanced load during palm kernel cracking and separating machine operation.

Solutions:

(1) Tighten or replace loose or worn-out components.

(2) Realign rotating parts to ensure proper operation.

(3) Balance the load distribution to minimize vibrations.

To sum up, by proactively addressing these common problems, you can maximize the efficiency, safety and profitability of your palm kernel processing operations. Regular maintenance and timely repair of palm kernel cracking and separating machine are key to avoiding costly breakdowns and ensuring consistent product quality. If you want to learn more about solutions to common problems in palm kernel cracking and separating machine, contact Henan Glory Company(with branch and overseas warehouse in Nigeria) today for a customized consultation. Beyond that, we can also provide you with a high-performance, high-performance palm kernel oil processing machines and provide reliable installation and operation support.