There are two kinds of method to remove free fatty acids from crude palm oil: chemical deacidification process and physical deacidification process. Their processes are different and the by-products are different, too.

Firstly, let us to learn about the chemical deacidification process. The chemical deacidification process uses the principle of neutralization of acid and base to remove free fatty acids from crude palm oil.

The chemical deacidification process flow chart of crude palm oil

The chemical deacidification process flow chart of crude palm oil

As the picture shows, after heating the crude palm oil, add alkali liquor , and then react for some time, settle for a long time, at last discharge the nigre out. The by-product of chemical deacidification process is exactly nigre, which is the raw material to make soap.

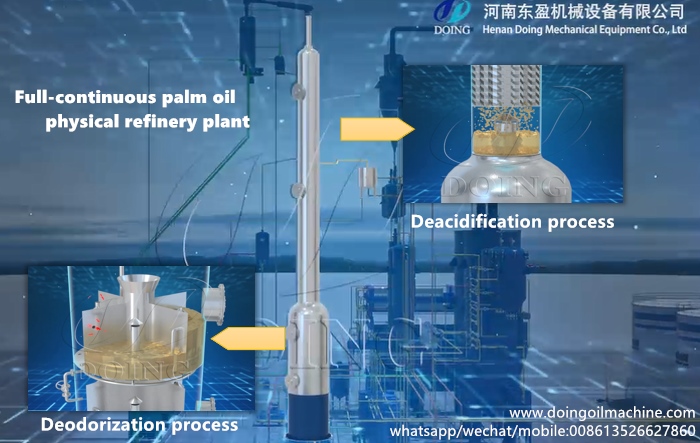

Next, it is about physical deacidification process. The physical deacidification process uses high temperature steam to take free fatty acid and odors off from palm oil at same time in vacuum comdition. It is finished in deodorization tower.

The functions of deodorization tower in palm oil refining process

The functions of deodorization tower in palm oil refining process

As the picture shows, the deodorization tower is divided into two parts. The free fatty acid is removed in the upper part, and the below is used to remove odors. In the process, the free fatty acid will be collected into FFA tank. Using physical deacidification process, the free fatty acid you get has high purity and higher market value, which can help you get more profits.

As a professional edible oil refining machine manufacturer, I must inform you that you need choose the deacidification process based on your requirement. You not only should consider what by-product you want to get, but also the actual input capacity of your palm oil refinery plant, and then decide which deacidification process is suitable for you.

If you want to set up a palm oil refinery plant, welcome to contact us! Doing Company can provide you high quality palm oil refining machine and help you design the suitable palm oil refining process according to your requirement.