Why does the crude oil need to be refined?

The crude oil except to principal containing oils and fats, it also have various impurities, such as, silt, oil cake and other solid impurities; phosphatide, protein mucus and other gel solubility impurities; free fatty acids, pigment, flavacin, other oil solubility and moisture impurity. The impurities above exists will be easy to cause oil rancidity, and lower the quality of oil and use value. So it needs to remove these impurities according to the properties of various impurities and different requirements, in order to meets the requirements of food oil.

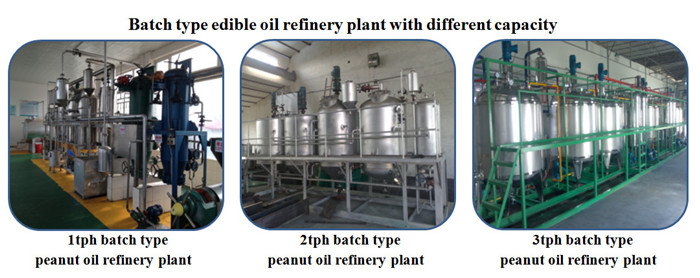

Various kinds of oil refining machine

The Oil Refining Machine is used for removing the impurities of oil, such as fatty acid, phosphatide, pigment. After the process of oil refining machine, the refined oil reaches the edible oil standard.The oil refining machine is suitable for refining various crude oil, vegetable oil, such as sunflower seed oil, tea seed oil, peanut oil, soybean oil, corn oil, groundnut oil and so on.

What is the refining process of oil refining machine?

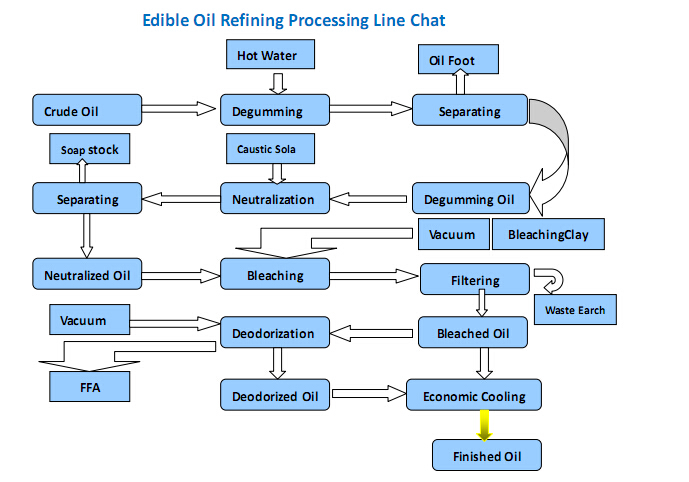

Cooking oil refining process

1. Degumming: Removing the phosphatide by adding hot water, when phosphatide meets hot water, it will become bigger and bigger, then out of tanks.

2. Deacidification: Removing the FFA by add alkali liquor (for taking neutralization reaction).

3. Decolorization(Bleaching): Remove the pigment by adding bleaching earth( it has strong adsorption of pigment), and the remaining bleaching earth will be filtrated by leaf filter.

4. Deodorization: Remove the oxide, solid particle and volatile gas.

5. Waxiness impacts palatability of oil; winterization/dewaxing focuses on increasing palatability of oil and impoving organoleptic properties such as transparency, brightness, etc. Waxiness content of different oils varies; winterization/dewaxing is necessary to oils like corn oil, sunflower seed oil, cotton seed oil, etc.

In general, freezing crystallization is widely used in winterization/dewaxing. In another word, reduce oil temperature and crystallize waxiness at first, and separate solid waxiness from liquid oil mechanically.

What is the main function of oil refining machine?

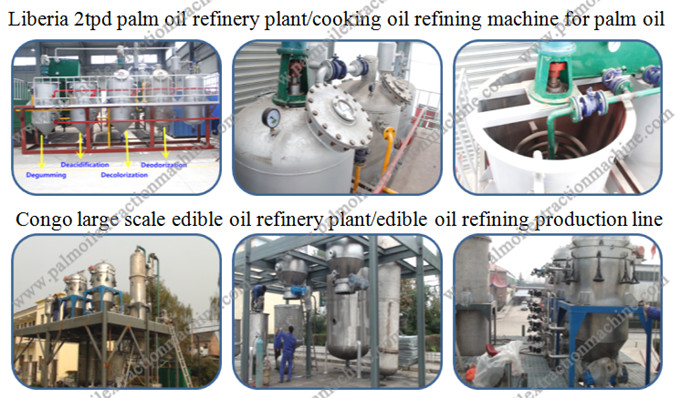

Oil refining machine we have installed in other countries

1.Hydration degumming

Hydration degumming is based on using the hydrophilia of phospholipid and other peptizing impurities to put certain amount of water or electrolyte dilute solution into crude oil under the action of mixing, so as to let the peptizing impurities of crude oil be water absorption and dilate, cohesion, separate and remove.

2.Alkali refining and deacidification

Alkali refining is using sodium hydroxide to neutralize free fatty acid of oils and fats, the generated soap can absorb other impurities so as to remove them from oil. The alkali refining educt are saponin.

3.Water scrubbing and drying

Water scrubbing and dewatering. Because influence of alkali liquor condition or limit of separating efficiency, the oil in process of alkali refining will vestigital little soap and alkali, so it has to reduce the residual volume through water scrubbing, and then do dewatering process, in order to prevent the deteriotation and emulsification of oil or affect subsequent decoloring.

4.Decoloring and deodorization

Decoloring and deodorization is using the stronger selectivity absorption materials for pigment, which can absorb pigments, peculiar smell, and other impurities in oils and fats, so as to achieve decoloring and deodorization.