Choosing the right oil press is a crucial step for any oil production business. The right choice can greatly affect the quality and quantity of oil production, as well as the overall efficiency of the production process. The following are the professional considerations for judging the quality and performance of the oil press to help you identify the quality of an oil press.

The material of the oil press plays a very important role in the quality of an oil press, ensuring the durability and stability of the machine. If the oil press is made of inferior metal, it is prone to corrosion, which may affect its performance and service life. The service life of Henan Glory's oil press can be as long as 20 years. The key components such as the screw and barrel also demand fine craftsmanship. The screw should be precisely designed and machined to apply appropriate and even pressure during the oil extraction process, enabling efficient squeezing of oil from the raw materials. The inner surface of the barrel should be smooth to ensure the smooth passage of the materials, reducing resistance and friction, thus saving energy and enhancing oil output efficiency.

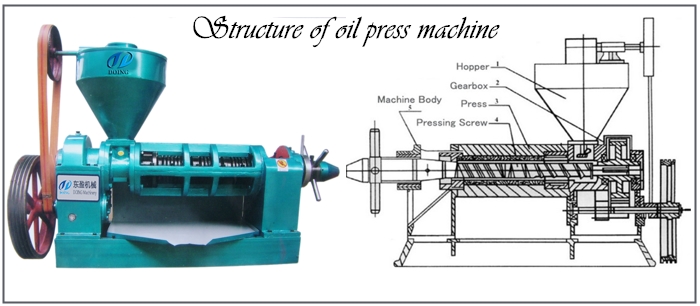

Structure of oil press machine

Structure of oil press machine

Moreover, a high-quality oil press should have a good shock and noise reduction design to ensure a smooth and quiet operation process. The precise assembly of all parts is essential. Tight and accurate assembly can effectively reduce vibration and noise during operation and lower the risk of breakdowns. Our oil presses will be polished twice before leaving the factory to ensure that you can use it immediately after receiving it. Ensure that the screw and the chamber are smooth.

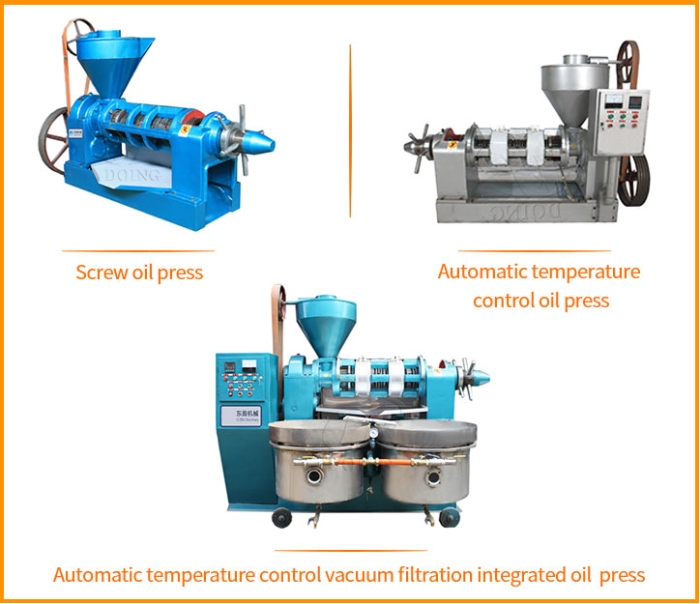

Different types of oil press machines

Different types of oil press machines

Oil extraction efficiency is a core indicator to identify the quality of an oil press. Our oil press can achieve the lowest residual oil rate on the market, which is 6%. In addition to the extraction rate, the quality of the extracted oil is equally important. A good oil press should possess an effective filtering system that can separate impurities such as fine particles of the raw materials and other debris from the oil. The extracted oil should be clear and free from excessive sediments, ensuring its purity and quality for consumption.

Safety is a top priority when using any electrical appliance. A reliable oil press should be equipped with multiple safety features. Henan Glory's oil press is easy to operate and extremely safe. Put the oil into the oil press and turn on the power. The oil press can run automatically. In addition, our company's equipment provides a one-year warranty and 24-hour online after-sales service after the equipment is successfully put into operation.

To sum up, identifying the quality of an oil press should be comprehensively considered in terms of material, oil yield, service life, use effect and warranty period. We are Henan Doing Holdings Henan Glory Oil & Fats Engineering Co.,Ltd,which is belong to Doing Holding. We are mainly engaged in vegetable oil raw material pretreatment, pressing, refining, solvent extraction, dewaxing, palm oil and palm kernel oil pressing, refining and fractionation, etc. Our company has the most advanced palm oil and edible oil pressing production technology, and undertakes edible oil production lines of various sizes. If you are interested, please contact us.