Soybean oil is an edible oil with a light and clean flavor that is commonly used for cooking. The oil is 60% polyunsaturated fat and 24% monounsaturated fat, according to the National Soybean Research Laboratory, making it a heart healthy oil. Soybean oil is extracted by several methods. Soy beans typically yield around 65% oil. Commercially, chemical extraction using hexane is common.For soybean oil processing plants with a capacity of less than 50 tons per day, small and medium scale soybean oil production lines are ideal for them. Cold pressing the beans using a small soybean oil press is the most available method for extracting the virgin soybean oil at home.

Soybean and soybean oil

Soybean and soybean oil

The production of commercial soybean oil is complicated. Soybean oil is normally produced by extraction with solvents. The production of soybean oil consists of the following steps:

Pretreatment of soybeans

Soybean pretreatment process

Soybean pretreatment process

First, the soybeans are cleaned, dried, softened and flaked before oil extraction. The cleaning process of soybeans mainly uses three equipments, vibrating screen, stone remover and magnetic separator, which are designed to remove impurities such as stones, magnets and leaves. To make oil extraction easier, the soybeans are also softened, and the temperature and moisture of the soybeans are adjusted. After the softening is completed, the soybeans are flaked, which can not only reduce the pressure of the soybean oil press, but also improve the oil yield of the soybeans.(Recommend reading:Soybean oil pretreatment machine)

Extraction of soybean oil

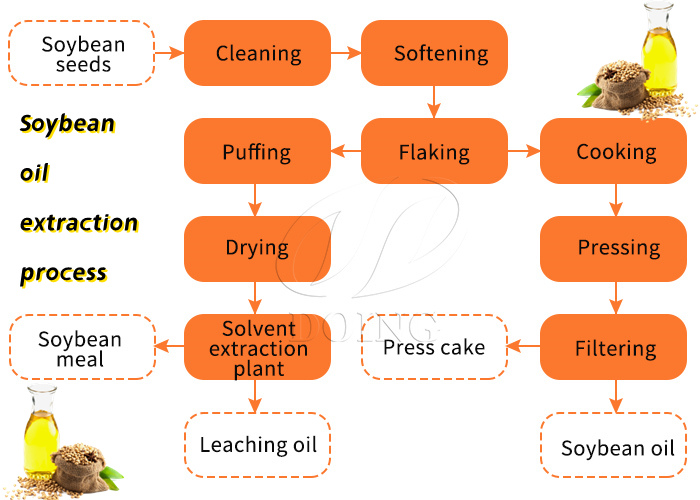

Soybean oil extraction process

Soybean oil extraction process

There are usually two processes for soybean extraction. One is to obtain crude soybean oil and soybean cake by cooking-pressing-filtering. The soybean cake can be processed to obtain soybean oil and soybean meal by solvent extraction. The second is puffing-drying-solvent extraction to obtain soybean oil and soybean meal.

During the puffing-drying-solvent extraction process, soybeans are placed in an extractor and soaked in a solvent, usually n-hexane. The countercurrent method is used as the extraction system because it has the highest yield. After removing n-hexane, the extracted soybean meal contains only about 1% soybean oil and can be used as livestock feed or to produce foods such as soybean protein. The n-hexane is separated from the soybean oil in the evaporator. The evaporated n-hexane is recovered and returned to the extraction process. The soybean oil is then further purified.

Purification of soybean oil

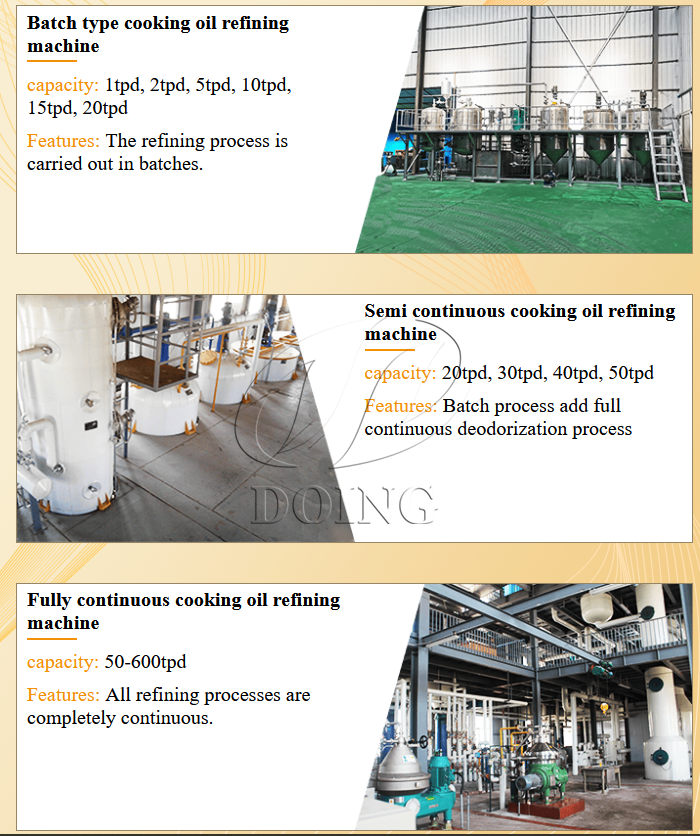

Soybean oil purification equipment

Soybean oil purification equipment

The crude soybean oil still contains many oil-insoluble and oil-soluble impurities that need to be refining. The oil-insoluble material is removed with filtration and the soluble materials is removed with different processes including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter, and gums) and bleaching (with activated earth or activated carbon to bleach and remove other impurities).

Henan Glory Company is a professional manufacturer and supplier of cooking oil process machine, cooking oil production line, etc. in China. We provide you with the latest cooking oil press quotation and the best after-sales service. Welcome to contact us!