How is palm kernel oil made from palm nut? Generally, there are two methods which can be used to make palm kernel oil from palm nut: pressing method and pre-press & solvent extraction method. The choice between the two methods is based on the daily capacity of palm nut. If the daily capacity of palm nut is more than 30T/D, using pre-press & solvent extraction method is wise, because the residual oil rate can be less than 1%. Then, Doing Company will elaborate the process of making palm kernel oil from the two methods in detail.

The first choice--pressing method

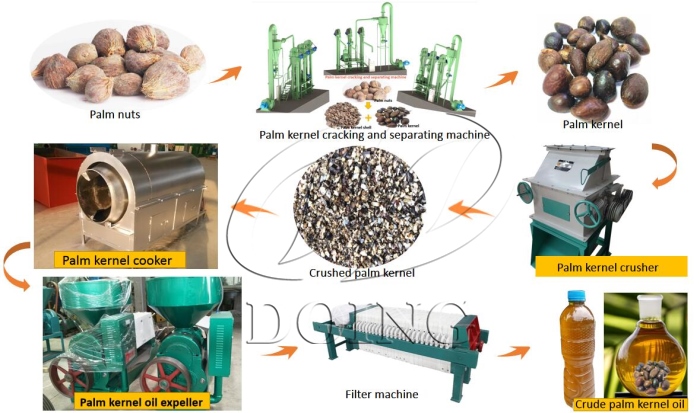

First, palm nuts are sent into palm kernel cracker and separator to break the palm nut, and to separate palm kernel and its shell. DOING Brand palm kernel nut cracker and separator can guarantee that the palm kernel is complete in cracking process and the separating rate can reach above 95%.

Next, the palm kernel enter into crushing machine, which can crush the palm kernel into small fragments, so as to make the palm kernel be heated evenly in the next cooking process.

Then, using cooker to adjust the temperature and moisture of palm kernel, and make it easier to be pressed by palm kernel oil presser.

After that, the prepared palm kernel will be sent to special-designed palm kernel oil presser to squeeze oil out. And we can obtain crude palm kernel oil. But there are still some impurities in crude palm kernel oil, so we need a simple filtration process.

Finally, using the plate filter to remove the impurities from crude palm kernel oil. And then the filtered oil will be sent into crude oil storage tank.

Palm kernel oil production process

Palm kernel oil production process

The second choice--pre-press & solvent extraction method

Using the pre-press and solvent extraction method to make palm kernel oil from palm nut, the palm nut also need pretreatment prior to pressing.

Next, use pre-press machine to get oil and cakes. Because the oil content of palm kernel is very high, which can achieve 50-55%. So it need be pressed firstly.

Then the cakes are sent into palm kernel oil solvent extraction workshop for further processing. It consists of four steps: degumming, deacidification, decolorization, deodorization. After the above four steps, we can get the crude palm kernel oil, and the dry meal which can be sold as animal feed.

Solvent extraction plant

Solvent extraction plant

The first method is suitable for small scale palm kernel oil mill plant, which its daily capacity is less than 10 T/D. While the second method is suitable for medium and large scale palm kernel oil mill plant. The biggest advantage of this method is that that the residual oil rate is less than 1%, avoiding oil waste.

It is worth noting that the oil obtained either from press way or pre-press & solvent extraction way is crude palm kernel oil. If you want to get pure palm kernel oil that can be sold in the supermarket, you also need to equip a set of palm kernel oil refining equipment. Henan Glory Company can also provide 1-1000tpd refining equipment for you. Welcome to contact us!