The main differences between pressing oil and solvent oil is the way to get oil. Pressing oil is got by the physical way, while the solvent oil is extracted by the chemical way. Compared with pressing, solvent extraction has higher oil yeild and lower labor cost with better work environment and better-quality cake.

Physical way is usually used for making the oil with flavor, such as peanut oil, sesame oil, etc. The oil residues in the cake is higher. The solvent way is used for the low oil content oil seed, such as soybean, rice, etc. The oil yield rate is higher and capacity is large. It also can be controlled by PLC, so it can be used in commercial process. Now the solvent extraction way is popular in the world. According to the raw materials, it also can use both pressing way and solvent extraction way.

Our cooking oil making machine can process various kinds of oilseeds

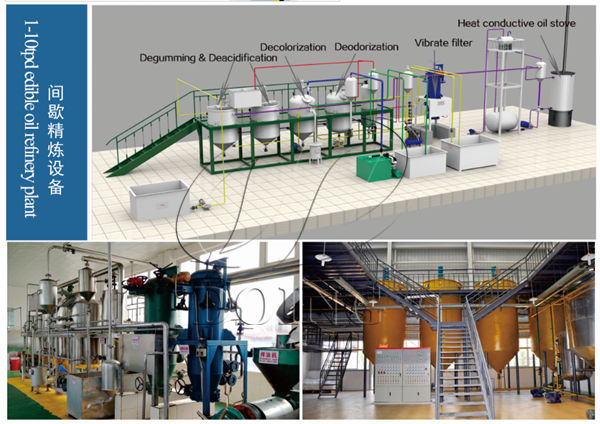

The oil which is got by pressing way and solvent way is called crude oil. After cooking oil refining machine, the edible oil is got. For making the flavor oil, the oil goes through degumming, deacidification and decolorization. If the crude oil is got by solvent way, it’s also need deodorization after above three steps. Some kinds of oil also need winterization to move the wax in it. For example, rice bran oil, sunflower oil and so on.