Vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (FFA) from oil; to impart uniform color by removal of colouring pigments and to get rid of unpleasant smell from the oil by removal of odiferous matter.

Vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (FFA) from oil; to impart uniform color by removal of colouring pigments and to get rid of unpleasant smell from the oil by removal of odiferous matter.

For processing less than thirty tones of oil per 24 hours, and when oil has F.F .A. content of 1 % or less normally batch process is recommended. Batch process involves low capital investment, simplicity of operation and low maintenance, making refining economically a viable proposition even at capacity as low as 10 tonnes per 24 hours.

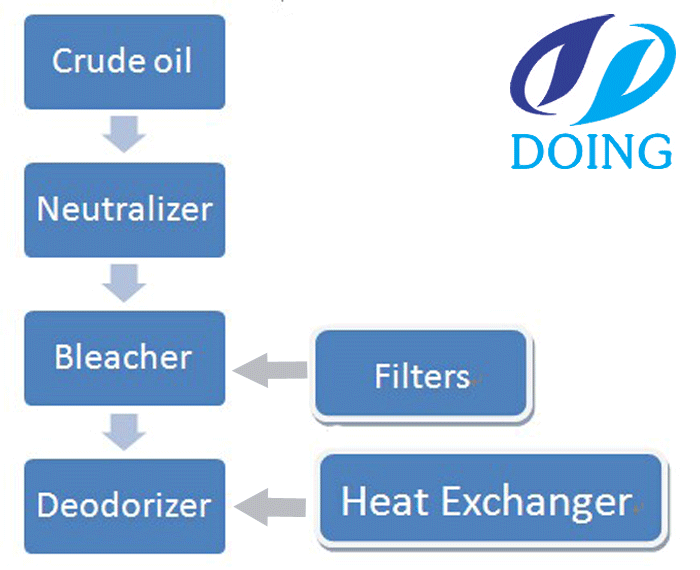

The equipment involved are neutralizer, bleacher, deodorizer, heat exchanger, high & low vacuum equipment & Filters. Troika plant with batch process have been operating at number of places, processing varity of vegetable oils.

Vegetable oil refinery