Home > Products > Oil pretreatment and press process Sunflower seeds pretreatment & pressing machines

Home > Products > Oil pretreatment and press process Sunflower seeds pretreatment & pressing machines

Sunflower seed pretreatment & pressing machines contain cleaning machine, husking machine, drying machine, flaking machine, cooking machine and sunflower oil pressing machine. They are high effective, automatic working and with mature technology. Henan Doing Company can design the sunflower oil processing plant according to your needs, including 5-10tpd small scale sunflower oil processing line and 30-1000tpd large scale sunflower seed pretreatment & pressing production line.

|

|

1. High oil yield & low waste 2. Stable performance 3. Unique design for each customer 4. Newest technology and automatic |

The oil content of sunflower seed is 40-60%, and sunflower seeds shell don't contain oil. Therefore, large scale sunflower oil processing plant must equip the sunflower seeds husking machine and kernel & shell seperating machine. If your sunflower oil processing plant is small scale, you can also choose to press the sunflower seeds with shell. According to actual situation, our engineers can design the most suitable sunflower seed pretreatment & pressing process for each customer.

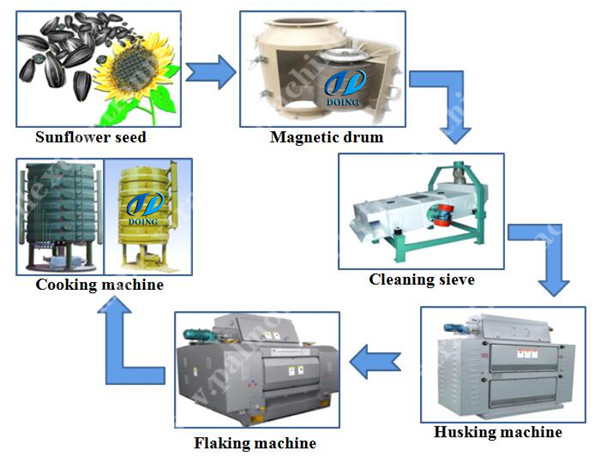

The usual sunflower seeds pretreatment process as follows:

Sunflower seed pretreatment machine and working process flow chart

Sunflower seed pretreatment machine and working process flow chart

The main function of the sunflower seed pretreatment process is to improve the sunflower oil quality as much as possible, and helps to get most oil from the sunflower seeds.

1) Magnetic drum: The first step is to move the iron in the sunflower seed, because the iron will harmful to the following sunflower seed pretreatment & pressing machines.

2) Cleaning sieve: After going through the cleaning sieve, the impurities in the sunflower seed will be cleaned.

3) Husking machine: The cleaned sunflower seed enter the husking machine to move the shell of the sunflower seed. The hulling rate is about 90%.

4) Separator of shell and kernel: The shell and nut will be separated by the separating sieve. First step is pre-separating. The shell rate is less than 2% after first separating. The second step is precise separating. The shell rate is less than 0.5% after this step.

5) Dryer: After separating the shell and nut, the nut will be dried under 60℃. Then the water content will be 8-9%.

6) Flaking machine: After the flaking roller, the thickness of cake is about 0.5mm.

7) Cooker: The cooker helps to adjust the water content of the material to 6-5kg/cm³.

8) Sunflower oil pressing machine: The crude sunflower oil is pressed by oil pressing machine. After moving the solid impurities in the crude sunflower oil, the oil will be clean.

After pressing, the sunflower cakes also can be extracted oil by solvent extraction way, and the crude sunflower oil can be refined to the best quality. If you want to set up a sunflower oil processing plant, please contact us.