Peanut oil pretreatment production line

Peanut oil pretreatment production line

Peanut oil pretreatment production line is the first step in peanut oil extraction process. Through peanut oil pretreatment production line, we can get crude peanut oil and pressed peanut cake, the crude peanut oil can eat directly or pump to peanut oil refinery workshop for further processing. The pressed cake can be send to penanut oil solvent extraction plant to extract more crude peanut oil. Henan Doing Company is a professional manufacturer of peanut oil pretreatment production line, we can design for you different peanut oil pretreatment production line as your requirement. Here we introduce you a common peanut oil pretreatment production line.{Recommend reading : Oilseed pretreatment & pressing machines ]

Features of peanut oil pretreatment production line:

1. Stable performance, high capacity

2. High process ratio

3. Unique design for each customer

4. Newest technology and automatic

Peanut oil pretreatment production line

Peanut oil pretreatment production line

The oil content of peanut kernel is 44-55%. Some customers’ peanut have shell. The process of peanut kernel and peanut with shell is different. According to the raw material, we can design the suitable peanut oil pretreatment production line for each customer. The main function of the peanut oil pretreatment production line is to move the impurities and adjust the peanut for getting high quality oil.

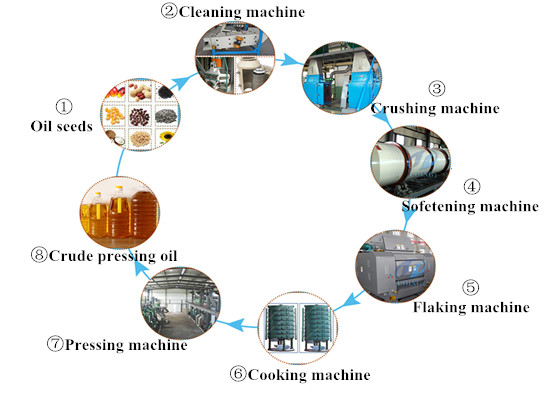

The usual peanut oil pretreatment production line as follows:

1) Magnetic:The first step is to move the iron in the peanut, because the iron will harmful to the following machines.

2) Cleaning: After going through the cleaning sieve, the impurities in the peanut will be cleaned.

3) Husking machine: The husking machine is to move the shell of peanut. The purpose of moving the shell is to improve the quality of oil and cake.

4) Separator of shell and nut: The shell and nut will be separated by the separating sieve.

5) Dryer: After separating the shell and nut, the nut will be dried under 60℃. Then the water content will be less than 4%.

6) Crusher: Peanut belongs to big size oil seed, so it need be broken down to small pieces. The function of the crusher in peanut oil pretreatment production line is to increase the area of oil seed and make the tempering easier. The peanut is divided to 6-8 pieces and the water content of crusher is 7-12%.

6) Flaking roller:After the flaking roller, the thickness of cake is about 0.5mm.

7) Cooker: The cooker helps to adjust the water content of the material to 6-5kg/cm³. It also can improve the oil yield rate of peanut oil pretreatment production line .

8) Oil presser: The crude oil is got by oil presser. After moving the solid impurities in the crude oil, the oil will be clean.

Peanut oil pretreatment production machine

Peanut oil pretreatment production machine

After the peanut oil pretreatment production line, the cake also can be extracted oil by solvent way or refined the oil to the best quality. The peanut oil can be made to different types. We can help you choose the suitable peanut oil pretreatment production line according to your market. If you want to know more about it, please contact us.