In general, the sections included in a palm oil processing plant are as follows:

Fruit cages and cranes are used to transport the fresh palm fruit bunches to the sterilization tank, where direct steam is used to sterilized the bunches at a high temperature, up to 145 degrees, for 60-90 minutes. Generally, palm oil processing plants are equipped with steam boilers to provide the required steam for the whole palm fruit sterilization process. Steam boilers include gas boilers and biomass boilers. In comparison, biomass boilers are more practical in palm oil processing plants because empty fruit bunches and fibers can be used as fuel to reduce costs.

In addition, the main functions of the sterilization process are:

(1) reduce FFA to avoid the deterioration of the fruit;

(2) soften the fruit bunches so that the fruit and empty bunches can be separated easily;

(3) cause the oil-containing cells to condense on the surface for easier pressing.

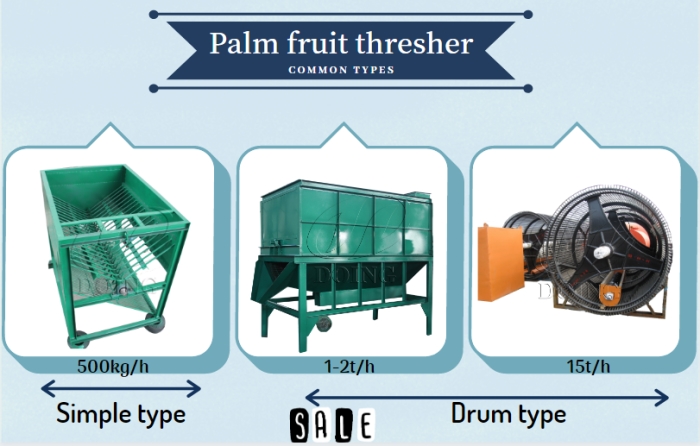

The function of the threshing section is to separate the palm fruits from the fruit bunches for subsequent pressing. The palm oil processing equipment used in this section is a palm fruit thresher. Henan Glory Company has specially designed two types of palm fruit threshers according to different processing capacities: simple type and drum type. The whole body of the drum type palm fruit thresher is made of high-strength carbon steel, so it is sturdy and durable. Its working principle is the interaction between the reamer and the flat steel inside the thresher. In addition, this drum type palm fruit thresher has a diameter of more than 1.2 meters and a length of 2.5 meters, which allows the fruit bunches to have enough running paths and achieve a 99% removal rate. The lower screw conveyor in the processing process is also 3 meters long, which can transport the fallen fruits to the next section.

Simple type and drum type palm fruit threshers

Simple type and drum type palm fruit threshers

As shown in the figure below, this section uses a vertical digesting tank to initially digest the palm fruit. The digesting tank is equipped with a reamer driven by a motor. When the palm fruit enters the digesting tank, it will be digested by these reamer. The digested pulp is more conducive to the subsequent palm oil press machine to squeeze it. In addition, the digesting tank is also connected to the steam boiler, which can ensure the palm oil won't be solidified in the process of digesting. The oil collecting tank under the digesting tank is also a unique design, which is used to collect the oil overflowed during the digesting process, avoiding too much oil into the oil presser to lower the working pressure, so this design can prolong the service life of the palm oil processing machine.

At this time, the digested fruit enters the palm oil press machine for the process of squeezing and extracting palm oil. In this regard, our Henan Glory Company has specially designed two palm oil press machines for customers to choose: single screw palm oil press machine and double screw palm oil press machine. Among them, the double screw oil press machine uses the relative rotation of double screws to squeeze palm fruit to obtain palm oil. And its manufacturing material is 2Cr13 alloy steel and one-piece casting process. At the same time, this palm oil press machine is also combined with a hydraulic pump station to realize the automatic adjustment of the pressure inside the chamber, so as to ensure that we can get the most palm oil as possible while not destroying the palm kernel inside.

Double screw palm oil press machine

Double screw palm oil press machine

Next, the palm oil will enter the filtering section, the whole filtering section involves three palm oil processing machines: vibrating screen, oil clarification tank and plate and frame filter.

(1) The crude palm oil is transported to the vibrating screen by screw pump, the vibrating screen is mainly used to filter large fiber impurities. It is made of stainless steel (316L), and the design of double-layer screen mesh can remove 95% of the impurity.

(2) Next is the oil clarification tank,this machine is to remove the sand and other heavy impurities in the oil. The clarification tank adopts the working principle of lower inlet and upper overflow, because the bottom of the tank is conical, the heavier sediment will stagnate at the bottom with the vortex, and the clean oil will slowly overflow into the oil hopper in the tank. There also are many steam coils in our oil clarification tank, which are used to keep the oil warm and ensure the fluidity of palm oil during the filtration process.

(3) At this time the filtered palm oil has been very clean, but in order to improve the quality of crude palm oil, we also need to use the plate and frame filter for the filtration of small impurities, the removal of impurities can reach 99%.

Three palm oil filtering machines

Three palm oil filtering machines

Finally, it enters our vacuum drying system, which removes water from the oil. Because we inject a lot of direct steam in the process of sterilization and digesting, which leads to the high moisture content in the oil and is not easy to store. So by using vacuum drying system, the water content of the oil can be less than 0.2% and the storage time can be up to half a year. Besides, our vacuum drying tank also has a steam coil to provide a heating environment for the oil. When the oil temperature reaches about 85℃ in the vacuum environment, the water will evaporate. This is the water jet vacuum pump which provides the vacuum environment.

The above are the palm oil processing sections included in the palm oil processing plant. The crude palm oil obtained through the above palm oil processing process is very clean and of good quality and can be stored in oil storage tanks for a long time. If you have any questions about the palm oil processing plant or palm oil processing machines, please feel free to consult us!