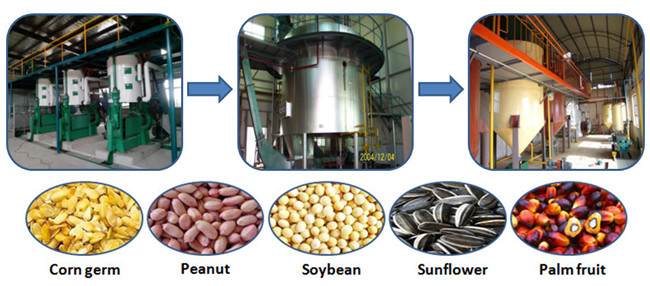

Vegetable oil production machine is open for producing natural and qualitative vegetable oil from high quality seeds of different kind of plants, such as sunflower, sesame, soybean, palm, cotton, peanut, rape and others.

Vegetable oil production machine includes few processes: pre-treatment and pre-pressing, extraction and refining.

Vegetable oil production machine

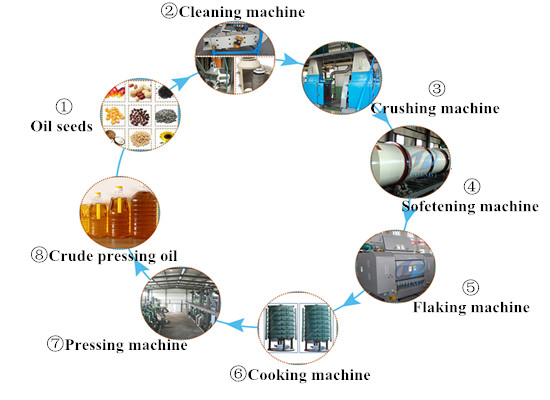

On the first stage of vegetable oil production machine,the seeds are going through cleaning, hulling, crushing, flaking, softening, cooking, pressing and filtering. For this process different types of pressing systems are used, according to a volume of output you need and also according to a type of seeds you are using to get certain oil. The oil pressing system as a rule contains a cleaning sieve, screw elevators, a cooker, a presser, a filter and a refiner. Vegetable oil production machine all depends on a model and design, which different companies can provide you. All seeds are going to a cleaning sector and after step by step to each mentioned sector to be ready for a next stage.

Vegetable oil pre-treatment and pre-pressing machine of vegetable oill production machine

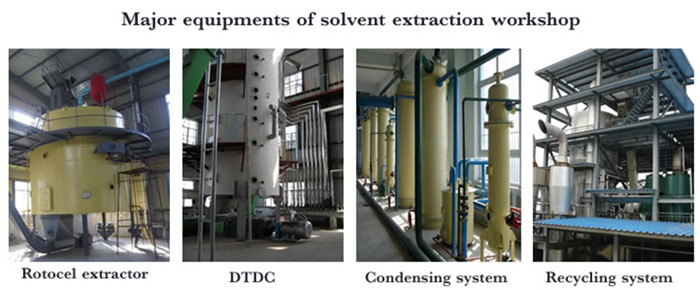

The second stage of vegetable oil production machine includes extracting, removing the solvent nature, evaporating, stripping and solvent recycling. Extraction process is the process, which means the separation oil from seeds. The pre-processed seeds are treated in a multistage counter current process with solvent. Then oil and solvent are separated by distillation. The solvent going into the extraction recycle process and the crude oil is ready for a next step. This process will keep production safety and provides a good quality.

Vegetable oil extraction machine of vegetable oill production machine

The last stage of vegetable oil production machine provides degumming, discoloring, deodorization, removing wax, fractionation etc. De-waxing section is optional. On the stage of degumming the oil separated from sand, after which it gets to be free from free-fatty acids and color pigments. Then the smell and odor are removed from the oil, because many seeds have special odors and smells, which many people don't like. So, the vegetable oil production machine will allow getting a high quality production of oil.

Vegetbale oil refining machine of vegetable oil production machine

Vegetable oil production machine is very comfortable for small family business. For small scale line it is required only 2-3 persons. This line requires also a smaller space for machines, which are oil press, oil filter, cooker and so on, of different designs from different producers, but making all these three processes, same as big plants are doing, and it will give a wonderful output.

Small scale vegetable oil production line is a wonderful opportunity to get a high quality vegetable oil inside of small family factory, without using so much space, time and sources for workers.

So, the main positive features of a small scale vegetable oil production machine are:

Simple structure

Saving of energy

Small size, light weight, small occupation area

Low investment

It is easy to operate and not difficult to maintain

Stable and durable

But to operate this small scale vegetable oil production machine you need to follow the instructions about how to keep all vegetable oil production machines in order, how to operate the step by step process, and, of course, to get a good oil you need to use high quality seeds.

Better to get a good pressing machine for the first stage of process, which is the most important. No need to economy also on other machines, involved in process. The quality of machines of vegetable oil production machine, same as the quality of seeds, guarantees you the best quality of vegetable oil.