Complete set palm kernel oil processing plant

The full set of Palm Kernel Oil procesing plant include palm kernel oil pressing machine, palm kernel oil refining machine and palm kernel oil fractionation plant. Plam kernel oil pressing proces is a mechanical proces that is important in the production of palm kernel oil. Palm kernel oil refining machine is a series of process includes Degumming Process,Neutralizing Process(Deacidification process), Bleaching Process, Deodorizing Process. After refining, we can get high quality palm kernel oil. As for, palm kernel oil fractionation plant, we uses mechanical separation of liquid oil from solid fractions of certain oil and fats, It can greatly maximize the value of products.

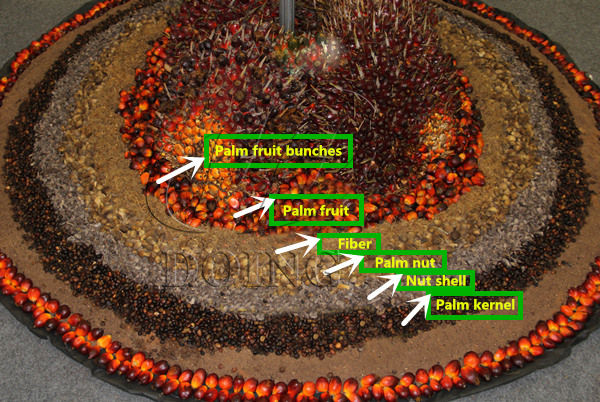

Palm fruit bunches, palm fruit, nut, net shell, kernel

Note:

Oil palm is the main oil crop in the tropical and subtropical region. Palm fruit is the most productive oil in the world. Palm pulp has 46 % ~ 50 % oil and palm kernel has 45 % ~ 50 % of oil. The oil extracted from palm fruit is called Palm Oil (PO), while, the oil obtained from palm kernel is called Palm Kernel Oil (PKO). They are two distinct oils and the extraction processes are also different. Below is the detailed information about how to extraction pko from palm kernel.

Main equipmen in palm kernel oil pressing process:

Small scale palm kernel oil pressing machine

Kernel and Shell Separation station:

Palm nuts cracking and separating machine is specially and newly developed to be used for cracking and separating palm nuts. It consists of palm nuts cracking machine and palm nuts kernel separator machine. The palm nuts cracking machine is mainly applicable for dividing the palm kernels into the outer hard shell with high efficiency. The separating machine is for separating the palm nuts kernels from the cracked shells clearly and completely. There are two different types with capacity of 200-300kg/h and 1000kg/h as your choice.Normally, the shell can be used as fuel in the boiler system. Palm kernel cracking and separating machine can improve the oil yield of pko, at the same time, improve the quality of pko and oil cake, minimize damages and maximize the effective production capacity of palm kernel oil making machines.

Palm kernel cracaking and separating machine

Palm kernel crushing station:

The palm kernel after Kernel and Shell Separation process is big in size, which will cause much damages for pko making machines if it is processed directly. Therefore, it is necessary to crush palm kernel into small piece so as to meet the requirements of palm kernel oil extraction process. The main machine for palm kernel is palm kernel cruhsing machine,also named palm kernel crusher.

Plam kernel Cooking station:

The main purpose of cooking is to completely destroy the cell of palm kernel by the effect of water and moisture, make protein denaturation, gather oil, reduce the oil viscosity and surface tension, adjust elasticity and plasticity of material and passivate enzymes. The main machine for palm kernel cooking is steam cooker.

Professional palm kernel oil pressing machine

Plam kernel Extraction/Pressing station:

The oil is extracted from pretreated palm kernel through mechanical forces. Palm Kernel Oil Extraction Machine is divided into two types: special palm kernel oil press machine and conventional palm kernle oil press machine.

Palm kernel oil clarifying and filtering station:

Purify the impurities within the oil by clarifying and filtering the crude palm kernel oil.

The quality of palm kernel oil obtained through above processing steps is high and enough to reach the standard of cooking oil. If there are special requirements, the palm kernel oil needs to be refined at professional

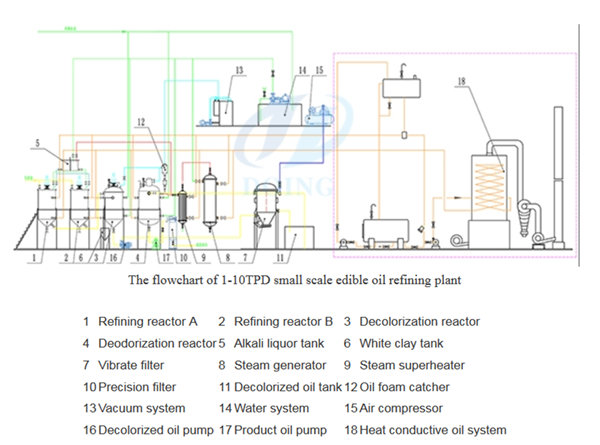

Palm Kernel Oil Refining Machine:

Palm kernel oil refining machine with capacity 1-20tpd

Palm kernel oil refining machine is vitally important in palm kernel oil processing machine.Our palm kernel oil refining machine can process various kinds of crude oil.Palm kernel oil refining is a step by step process.Our palm kernel oil refining machine including a series of refining processes which are aim to remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities from crude edible oil.

Process flow chart of palm kernel oil refining machine :

Palm kernel oil refining process flow chart

Heat conduction furnace: 1 set Offer enough thermo for the refining sections.

Steam generator: 1 set Produce steam for the workshop

Refining Pot: 2 sets Remove the gum, phosphoric acid etc

Decolorization Pot: 1 set Remove the color from neutralized oil

Deodorization Pot: 1 set Remove the solvent, smell, water from decolorized oil

Other Auxiliary Equipments: Alkali liquor tank, White clay tank, Air compressor, pumps, filters, Valves, Electricity Control Cabinet, etc.

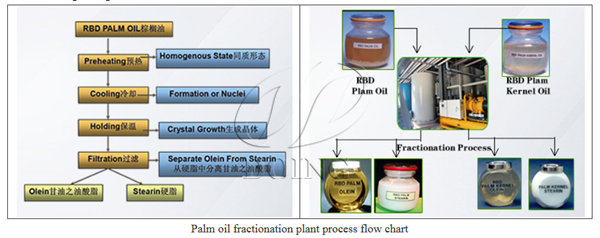

Palm kernel oil fractionation plant:

Palm kernel oil fractionation process flow chart

Palm kernel oil fractionation plant goes through the control of palm kernel oil cooling and crystallization to make separation of palm kernle oil into low melting point liquid (soft fat) and high melting solid (sterin). Fractionation of palm kernle oil can be divided into three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm midfraction).

Working principle of palm kernel oil fractionation plant:

Palm kernel oil fractionation plant uses mechanical separation of liquid oil from solid fractions of certain oil and fats. It can greatly maximize the value of products.

Featured Advantages of plam kernel oil fractionation plant:

◆Simple oil fractionation process

◆Easy and convenient operation

◆Low consumption of steam

◆No environmental pollution

◆Satisfied palm kernel oil fractionation results

We industry leading manufacturer in palm kernel oil processing field. We provide full set of palm kernel oil processing plant with factory prices. We also supply turnkey projects for pko mill plant and palm kernel oil refinery plant. If there are any needs, please contact us for more details and latest price!