Sunflower oil refining machine workshop

Sunflower oil refining machine refers to a series of refining processes that can remove phospholipids, FFA, pigment, off-flavor and other impurities in the oil. Sunflower oil refining machine usually includes the following sections: Degumming, Neutralization, Bleaching, Dewaxing and Deodorization.

Automatic sunflower oil refining process is a little different with other vegetable oil refining, because sunflower oil contains too much wax, then except normal vegetable oil refining process, we need add dewaxing after oil refined in sunflower oil refinery process. With dewaxing, sunflower oil will keep transparent and clear even in winter.

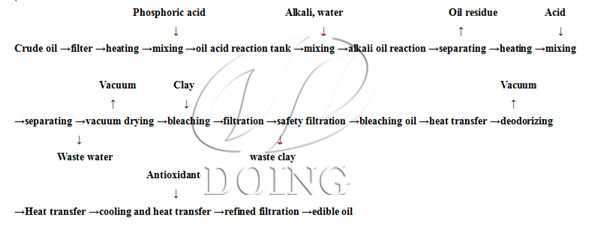

1. Sunflower oil refinery process flow chart:

Sunflower oil refining process flow chart

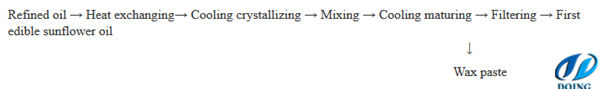

2. Sunflower oil dewaxing process flow chart:

Sunflower oil dewaxing process flow chart

Quantitive crude sunflower oil is pumped to pipe filters; then filtered oil is sent to heat exchanger. Heated oil is mixed with phodphoric acid in the sunflower oil refining machine before going to the reaction tank. After reaction and cooling, the oil enters another mixer to mix with caustic alkali liquid to neutralize. The neutralized oil enters the centrifugal to separate soap from oil. Separated oil still contents some quantity of soap that should be removed. By mixing with hot water, the oil is washed. Then a centrifugal is used to separate the water with residual soap from oil.

De-gummed and neutralized oil is pumped into vacuum drier, and then dried oil is cooled by a heat exchanger and sent into a storage tank. De-gummed and neutralized oil is sent to bleaching section to bleach. Oil to be bleached is pumped to mixed tank and heating tank separately. A proportion of oil to be bleached is pumped into a mixing tank to mix with dosed bentonite, and another part of oil to be bleached is pumped to the heater. The mixture and the heated oil go into the bleaching tank to de-colourize. Consequently, the mixture of oil and bentonite is pumped into leaf filter to remove deposable bentonite.

Parallel leaf filters make it possible to perform continuous operation of bleaching of sunflower oil refining machine. Filtered oil is pumped into the storage tank after being cooled in a heat exchanger and filtered safely.

Sunflower oil refining

Apply current advanced sunflower oil refining machine technology combining with traditional chemical and international-popular physical refining technology;

Mixer:With sunflower oil refining machine, material liquid can be mixed with acuity in a short time to meet the requirement of process;

Both short mixed and long mixed process are adapted in washing sector, which ensures washing effectiveness;

Continuous vacuum drier has high drying efficiency;

Heat exchangers has high heat transferring efficiency;

Decolorizing tower is used in bleaching section, which can save energy and reduce the leakage of vacuum due to machinery stirring;

Equipped with vertical leaf filter to remove used bentonite from the oil, operating conveniently and continuously, low laboring tense, keeps environment well, keeps oil residence in deposable bleaching earth in low level.

Winterization de-waxing system is capable of winterize various kinds of oil with the same set of sunflower oil refining machine. For instance: sunflower oil, cotton seed oil.

Cooking oil refining machine we have installed

The crude sunflower oil refining machine is suitable for both large or medium scale oil plants. The whole line process can deal with various kinds of crude oil, such as crude soybean oil, crude peanut oil, crude rapeseed oil, crude palm oil, etc.

Henan Doing Company is a professional manufacturer of sunflower oil refining machine, we can design sunflower oil refinery for you as your requirement and offer turnkey project oversea services including sunflower oil refining machine installation, commission, training workers etc. until sunflower oil refinery start-up.