Rapeseed oil extraction process

September 19, 2017 18:23

Rapeseed oil solvent extraction process machinery

Rapeseed oil extraction process is one of important process of rapeseed oil production. We can choose proper rapeseed oil extraction process according to production capacity .

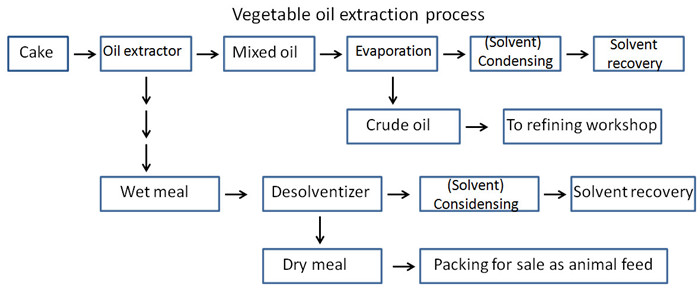

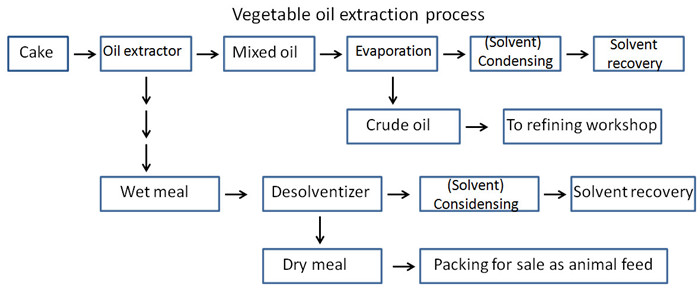

Rapeseed oil extraction process:

Rapeseed oil extraction process

After rapeseed pre-pressed, pressed rapeseed cake will be delivered to rapeseed oil solvent extraction machine to extract oil with solvent inside oil extractor, after extraction, will get mixed oil and wet meal. Mixed oil will be separated with solvent by multi-effective evaporators. Wet meal will be dried and separated with solvent inside desolventizer. Solvent will be collected and reused through condensers.

Main equipments of rapeseed oil extraction machine:

1. Solvent oil extractor

Oil extractor is most important equipment used in rapeseed oil solvent extraction process. It can be divided into batch oil extractor and continuous oil extractor. Batch oil extractor is used for small capacity rapeseed oil extraction. Common used continuous oil extractor is rotocel oil extractor, loop type oil extractor, towline oil extractor etc.

Rotocel extractor and loop type extractor

2. Wet meal desolventizer

Discharged from oil extractor, wet meal contains 25-35% solvent, in order to reuse this solvent and get good quality of meal, using desolventizer to steam evaporate solvent.Desolventizer normally is high layers steam desolventizer.

3. MIxed oil evaporators

Using multi-effective evaporators to separate solvent with oil because of different boiling point. Multi-effective evaporators is the key equipments in rapeseed oil solvent extraction process.Multi-effective evaporators includes first evaporator, second evaporator and stripping tower. After first and second evaporators , most solvent is transformed into gas by high temperature steam. And then stripping mixed oil to remove residual solvent in order to get low solvent residual crude oil.

4. Solvent condensing and cooling

Solvent gas from first and second evaporator doesn't contain water, can be recycling directly after cooling by condensers. Solvent gas from stripping tower and desolventizer is mixed with steam, which need to separate with water by water distributor after condensers.Common condenser is tube nest condenser.

For big capacity more than 100 t/d, rapeseed oil solvent extraction process can adopt negative pressure oil extraction.