Soybean oil plays a crucial role in culinary endeavors and everyday meal preparation. Behind the scenes, the production of soybean oil involves a meticulous process that transforms raw materials into the familiar and essential product we use daily. The soybean oil production line is a series of interconnected sections, each playing a vital role in ensuring the quality, purity, and safety of the final product.

The journey of soybean oil begins with the selection and preparation of the raw materials. In this section, the soybeans undergo cleaning, sorting, and conditioning processes to remove impurities, dust, and unwanted particles. The goal is to provide a clean and uniform soybean base for the subsequent extraction processes.

Soybean pretreatment machines

Soybean pretreatment machines

After cleaning, the soybeans also need to be broken, softened, flaked, etc. Because seed size and moisture content will affect seed oil yield. Different seeds require different pretreatment processes. Henan DOING Company will provide you with different soybean pretreatment machines to ensure maximum oil yield.

The heart of the soybean oil production line lies in the oil extraction section. Various methods are employed, including mechanical pressing, solvent extraction, or a combination of both, depending on the type of oilseed. Mechanical pressing involves physically squeezing the oil out of the seeds, while solvent extraction utilizes chemical solvents to dissolve and extract the oil. This section is pivotal in obtaining the maximum yield of oil from the seeds.

Soybean oil extraction machines

Soybean oil extraction machines

If your daily processing capacity is less than 20 tons, you can choose mechanical pressing method, otherwise, choose solvent extraction. We can supply these two different edible oil production line machines.

This oil refining section is also an important section of the soybean oil production line, which can refine crude oil into edible oil with national food standard. The extracted crude soybean oil undergoes refining to remove impurities, undesirable flavors, and odors. The refining section typically includes degumming, neutralization, decolorization, and deodorization processes. Degumming removes phospholipids, neutralization addresses free fatty acids, decolorization eliminates pigments, and deodorization removes volatile compounds responsible for off-flavors and odors. The result is a clear, colorless, and odorless refined oil ready for consumption.

Soybean oil refining machines

Soybean oil refining machines

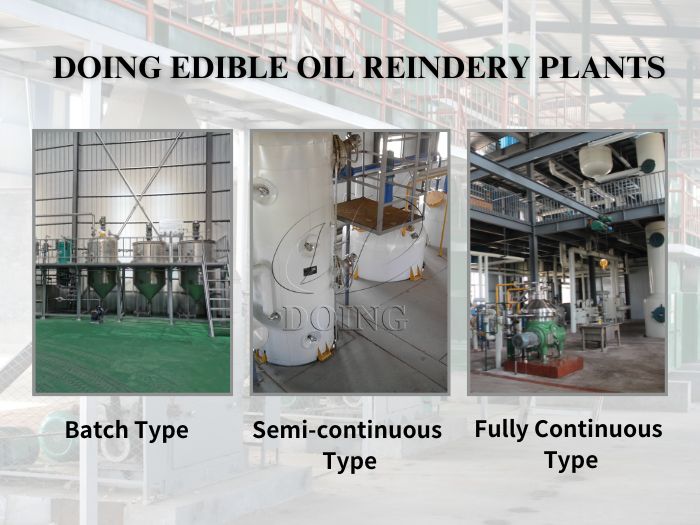

Depending on the processing capacity, we have designed different types of refining machines of soybean oil production line: batch, semi-continuous and fully continuous type soybean oil refining machine.

The above is an introduction to the section of the soybean oil production line. We are a top Chinese soybean oil production line machines manufacturer and supplier. We have rich experience. If you're planning to process soybean, or other oil seeds, such as sunflower seeds, peanuts, palm fruit, palm kernel, sesame, rapeseeds, cottonseeds, etc, welcome to consult us at any time.