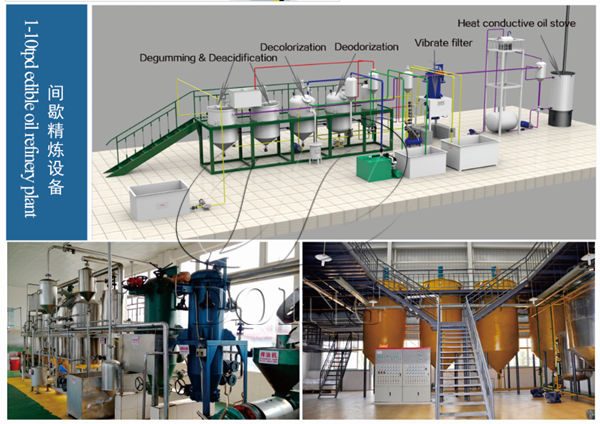

The process of edible oil production process can be roughly divided into pretreatment pressing section, leaching section and refining section. Among these three processing sections, edible oil refining section is an important way to increase the market value of refined oil, and refining can be divided into three types: batch type, semi-continous type, full continous type. Refining methods correspond to different processing capacity and refining effects, but all these four edible oil refining process includes four sections: degumming, deacidification, decoloration, deodorization. Below I will introduce you the process and principles of these four stages in turn.

Batch type cooking oil refining machine

Batch type cooking oil refining machine

Degumming section: There are some phospholipid, gum, and protein, the can be dissolved into oil when there is no water, but once there is water in oil, these impurity can be dissolved into water. So, in degumming section, we use the hot water to wash crude edible oil for two-three times to make gold phospholipid condenses and reduces colloid, and it can remove these impurity.

Deacidification section: add some water and based on suitable temperature, usually need several hours open the below valve release the gum, then add some chemical materials for remove the acid materials, such add alkali liquor and stirring, then open the below valve release the soapstock, so if the crude oil FFA high, will lost much oil and get much soapstock, this materials can make further process for producing soap, cosmetic, ect.

Decoloration section: usually using White Clay, decolorization is carried out by the obsorption function of white clay, this step usually need 25mins, temperature requirements around 105-110 Celsius.

Deodorization section: This step have high temperature requirement , around 260 Celsius, based on very high temperature, steam removes oxidation number, aldehydes, and ketones, and take off some of the acid, the smell will be evaporated.

Edible oil refining mahcine can refine the above vegetable oils

Edible oil refining mahcine can refine the above vegetable oils

Do you want to set up a edible oil refinery plant? We have the professional engineers team and rich experience. If you have any other questions about the edible oil refinery plant, please contact us! Henan Glory Oils & Fats Engineering Co., Ltd will give you most suitable suggestion about your edible oil refinery plant.