Edible oil refinery refers to a series of refining processes that can remove phospholipids, FFA, pigment, off-flavor and other impurities in the oil. Edible oil refinery or vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil. After edible oil refining process, the edible oil is more palatable and stable against rancidity upon storage.

Edible oil refinery plant usually includes the following sections: Degumming, Neutralization, Bleaching, Dewaxing and Deodorization.

Small scale edible oil refinery plant

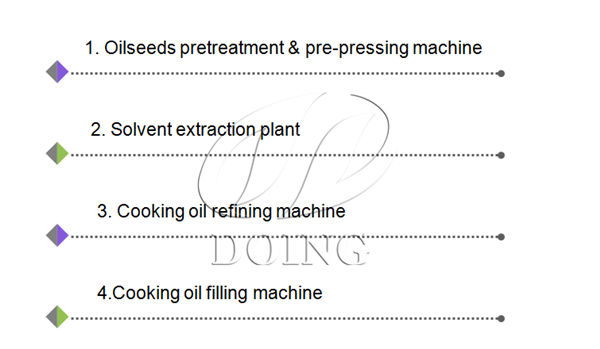

Cooking oil refinery process flowchart:

Cooking oil refining process flow chart

Main equipments of cooking oil refinery line:

Neutralization pot: Use for acid refining, alkali refining and water washing.

Decolorization pot: Use to bleach oil and remove pigment.

Deodorization pot: Use to remove odors of oil (the material is stainless steel).

Heat conduction oil furnace: Provide heat energy for small edible oil refinery machine production, which temperature can reach 280℃.

Vacuum pump: Provide the needed vacuum degree of decolorization and deodorization, which up to above 755mgHg.

Air compressor: Dry bleaching clay.

Filter press: Filter bleaching clay.

With Over 10 years/ experience of designing & installing & exporting complete oil refinery plant like vegetable oil refinery, we are now the leading company in edible / vegetable oil refinery field. We supply various edible / vegetable oil refining equipment and technology to ensure that best finished oil is achieved with the lowest production cost. If you'd like to get more information about our cooking oil refining machine, please contact us in the following form. We are always at your service.